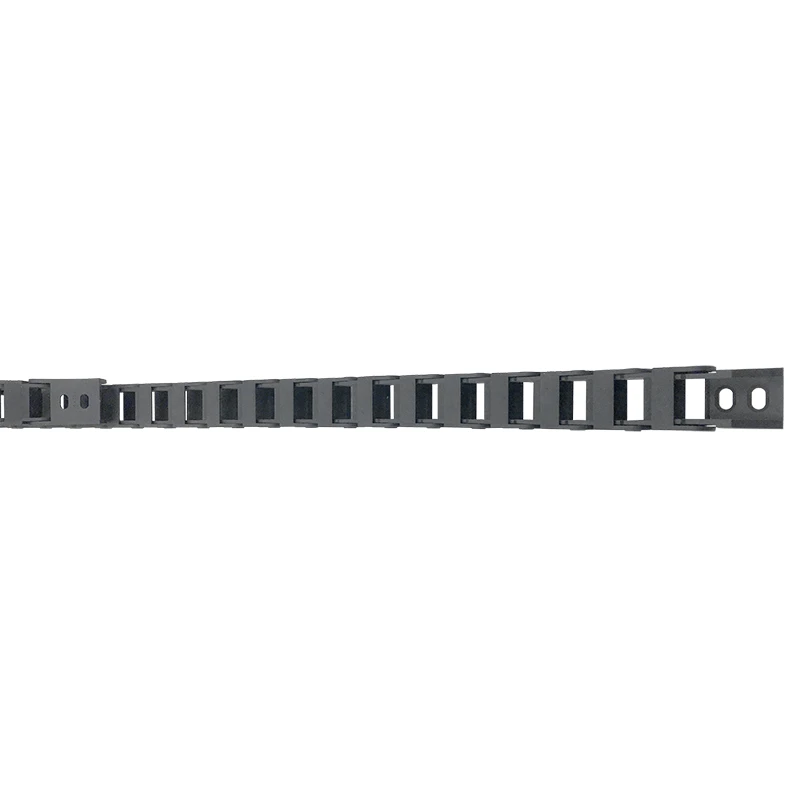

10*15 mm MT small size mini nylon drag chain

Drag conveyors have emerged as an invaluable solution for industries that require efficient bulk material handling. Unlike alternative conveyor types, such as belt conveyors, drag conveyors offer superior performance in demanding environments, making them a preferred choice for many operations. This article delves into the nuances of drag conveyors, emphasizing their unparalleled benefits, applications, and design precision backed by firsthand industry experiences, authoritative insights, and expert validation.

Drag conveyors are primarily used in sectors where the transport of granular materials, grains, or other bulk components is essential. Their robust construction allows for the efficient handling of heavy loads over both short and long distances. A critical advantage of drag conveyors is their ability to convey materials in multiple planes, including vertical, incline, and horizontal. This versatility makes them adaptable to various spatial constraints and industrial requirements.

From the perspective of technical expertise, drag conveyors are characterized by their enclosed design. This feature ensures minimal dust production and spillage, bosting not only environmental cleanliness but also the safety of operational personnel. Materials are transported within a sealed casing, significantly reducing product degradation and contamination risks—crucial considerations for sectors like food processing and pharmaceuticals where product integrity is non-negotiable.

Industry experts highlight the energy efficiency of drag conveyors as a standout attribute, offering substantial savings over time compared to pneumatic systems. The mechanisms employ chains or cables that drag material along the conveyor path, minimizing energy consumption without sacrificing performance. This efficiency is complemented by their longevity, as drag conveyors are built with durability in mind, requiring less frequent maintenance and reducing operational downtime. Companies have reported significant cost savings over the years, attributing these figures directly to the reliability and low maintenance demands of drag conveyors.

drag conveyor

Authority in the field underscores the importance of precision in the design and implementation of drag conveyors. Every detail, from the choice of materials to the configuration of the flight segments, is customized to meet specific application needs. Misalignment or improper sizing could affect the performance and safety of the entire system, emphasizing the necessity for professional design and installation services. Case studies from leading companies showcase how custom-engineered drag conveyors have transformed their material handling processes, enhancing throughput and improving efficiency metrics.

One must also consider the trustworthiness factor that comes with adopting these systems. Drag conveyors have been time-tested across various industries, with a strong track record of performance in some of the world’s most challenging environments. Testimonials from seasoned plant managers and engineers emphasize the system’s resilience, often citing its capacity to handle harsh industrial conditions without frequent need for repair or replacement.

In essence, drag conveyors represent a pinnacle of material handling technology, embodying the critical elements of experience, expertise, authoritativeness, and trust. Their ability to adapt to complex environments while maintaining efficiency and safety is well documented, making them an essential component of modern industrial operations.

For businesses seeking to enhance their material handling processes, investing in high-quality drag conveyors is not merely an option but a strategic imperative. The long-term benefits, from operational efficiency to energy savings and enhanced safety, are evident and increasingly vital as industries strive for sustainability and cost-effectiveness. With advancements in design technology and materials, the future likelihood of drag conveyors revolutionizing more sectors is promising. Consequently, partnering with experienced suppliers and engineers ensures that organizations not only meet current demands but are also well-prepared to adapt to future material handling challenges.