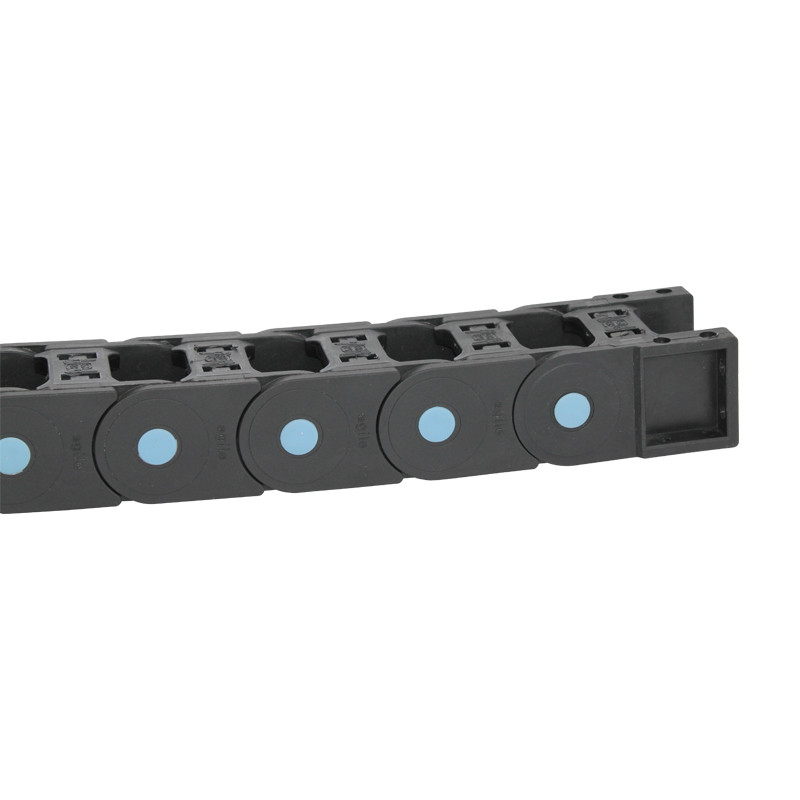

dust cover bellows

The Importance of Dust Cover Bellows in Industrial Applications

In various industrial environments, equipment often faces the challenge of exposure to dust, debris, and other contaminants. To mitigate this risk and ensure the longevity and efficiency of machinery, dust cover bellows play a crucial role. These protective covers not only enhance the operational lifespan of machinery but also contribute to maintaining optimal performance levels.

What are Dust Cover Bellows?

Dust cover bellows are flexible, accordion-like enclosures typically made from materials such as rubber, PVC, or other durable polymers. Their design enables them to expand and contract, making them ideal for use in applications where movement is a factor. They are primarily used to protect moving parts from dust, dirt, and moisture, therefore preventing wear and tear caused by these contaminants.

Key Benefits of Dust Cover Bellows

1. Protection from Contaminants The primary function of dust cover bellows is to provide a barrier against dust and debris. In applications like CNC machines, telescopic lifts, and conveyor systems, exposure to particulates can drastically impact performance. Bellows effectively seal off critical components, ensuring smoother operation.

dust cover bellows

2. Enhanced Equipment Life By protecting machinery from potential contaminants, dust cover bellows contribute to an extended lifespan of equipment. This translates to reduced maintenance costs and lower frequency of replacements, ultimately leading to significant savings for businesses over time.

3. Versatility Available in various shapes, sizes, and materials, dust cover bellows can be tailored to fit a wide range of applications. From automotive to aerospace, their versatility makes them indispensable in multiple industries.

4. Ease of Installation Most dust cover bellows are designed for easy installation, allowing businesses to retrofit existing equipment without extensive modifications. This ease of use means minimal downtime during the installation process, which is crucial in fast-paced industrial settings.

5. Aesthetic Appeal While functionality is paramount, the design of dust cover bellows can also contribute to the overall aesthetics of machinery. Modern bellows come in various colors and finishes, enabling businesses to maintain a professional look while ensuring their equipment is well-protected.

Conclusion

In conclusion, dust cover bellows are an essential component in the protection and maintenance of industrial equipment. Their ability to shield moving parts from dust and debris, combined with their versatility and ease of installation, makes them ideal for a multitude of applications. As industries continue to prioritize operational efficiency and equipment longevity, the adoption of dust cover bellows is likely to grow. For businesses looking to enhance their machinery's performance while minimizing maintenance costs, investing in quality dust cover bellows is a wise and strategic choice. By safeguarding the integrity of their equipment, companies can ensure not only the smooth operation of their processes but also their continued success in a competitive marketplace.