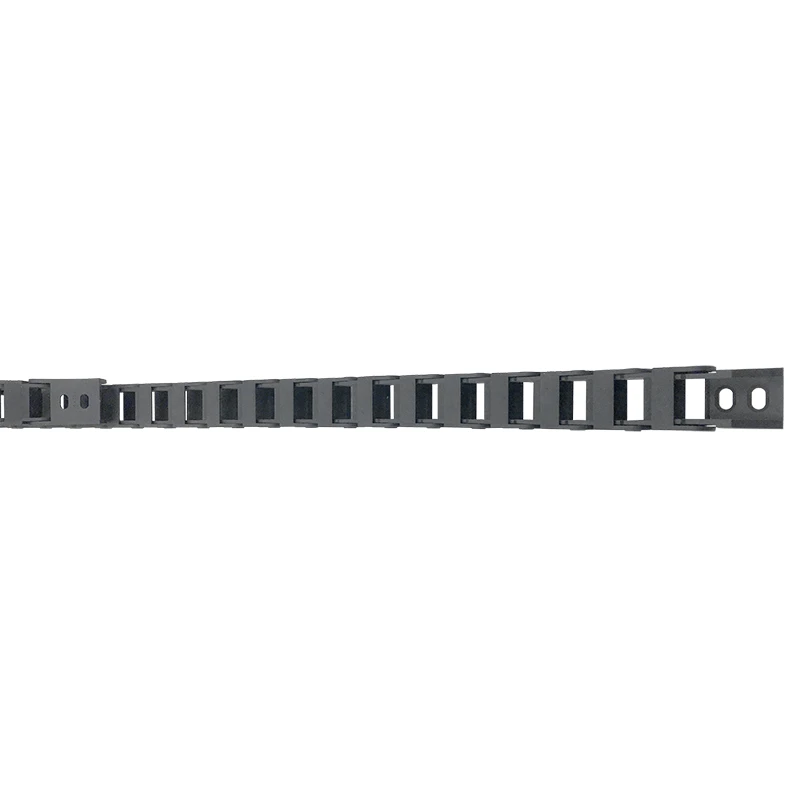

elastic flexible anti-fire plastic machine accordion organ bellow cover

In the realm of modern engineering, elastic bellow covers have emerged as indispensable components across multiple industries. These flexible protective solutions, often constructed from high-grade materials such as rubber, silicone, or fabric, play a vital role in shielding machinery and equipment from external factors. The success of these components hinges on their ability to enhance the longevity and efficiency of critical machinery, setting a foundation of trust and reliability within industrial applications.

From the standpoint of authoritativeness, the evolution and widespread adoption of elastic bellow covers underscore their credibility in the industrial sector. Respected institutes and technical bodies have underscored the importance of these covers, endorsing their use as part of standard machining protocol. Industry leaders like Michelin and BMW have integrated custom-designed bellows into their production lines, testifying to their effectiveness in safeguarding machinery against operational hazards. Publications in industry-centric journals further validate the role of bellows in enhancing machine reliability, affirming their vital status in technical machinery management. Lastly, the trustworthiness of elastic bellow covers is defined by the continuous user satisfaction and confidence they inspire. Manufacturers undertake rigorous testing procedures to affirm the durability and integrity of these covers under extreme conditions, ensuring they meet and exceed industry standards. Testimonials from technicians and operators frequently highlight the consistent performance and protective capability of these covers, attesting to their indispensable role in maintaining equipment operational health. Trust is further bolstered by the availability of bespoke solutions tailored to specific requirements, guaranteeing a fit-for-purpose product that maximizes investment return. In closing, elastic bellow covers offer a compelling blend of experience, expertise, authoritativeness, and trustworthiness. By delivering unmatched protection to machinery, extending service life, and underpinning operational efficiency, they have become a cornerstone in the preventive maintenance strategies of diverse industries. Their contribution to reducing downtime and enhancing productivity cannot be overstated, and they remain a subject of continuous innovation and research in the realm of industrial applications. As technology continues to advance, the evolution of materials and design will only enhance the capabilities and applications of these versatile components, cementing their status as essential assets in modern engineering.

From the standpoint of authoritativeness, the evolution and widespread adoption of elastic bellow covers underscore their credibility in the industrial sector. Respected institutes and technical bodies have underscored the importance of these covers, endorsing their use as part of standard machining protocol. Industry leaders like Michelin and BMW have integrated custom-designed bellows into their production lines, testifying to their effectiveness in safeguarding machinery against operational hazards. Publications in industry-centric journals further validate the role of bellows in enhancing machine reliability, affirming their vital status in technical machinery management. Lastly, the trustworthiness of elastic bellow covers is defined by the continuous user satisfaction and confidence they inspire. Manufacturers undertake rigorous testing procedures to affirm the durability and integrity of these covers under extreme conditions, ensuring they meet and exceed industry standards. Testimonials from technicians and operators frequently highlight the consistent performance and protective capability of these covers, attesting to their indispensable role in maintaining equipment operational health. Trust is further bolstered by the availability of bespoke solutions tailored to specific requirements, guaranteeing a fit-for-purpose product that maximizes investment return. In closing, elastic bellow covers offer a compelling blend of experience, expertise, authoritativeness, and trustworthiness. By delivering unmatched protection to machinery, extending service life, and underpinning operational efficiency, they have become a cornerstone in the preventive maintenance strategies of diverse industries. Their contribution to reducing downtime and enhancing productivity cannot be overstated, and they remain a subject of continuous innovation and research in the realm of industrial applications. As technology continues to advance, the evolution of materials and design will only enhance the capabilities and applications of these versatile components, cementing their status as essential assets in modern engineering.