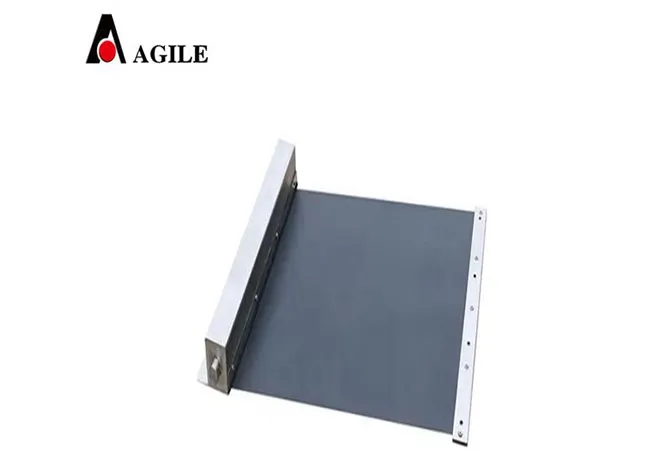

elastic bellow cover

Elastic bellow covers, essential components in a myriad of industrial applications, serve as protective shields for sensitive equipment parts. Highly valued for their flexibility, durability, and adaptability, these covers prevent dust, dirt, moisture, and other contaminants from compromising equipment performance. With the growth in automation and precision engineering, the demand for high-quality elastic bellow covers is on the rise.

Elastic bellow covers also play a pivotal role in maintaining clean and hygienic environments, particularly in the food processing and medical industries. In these sectors, safeguarding processes from contamination is not only a regulatory requirement but also essential for product quality and safety. Elastic bellow covers ensure that particulate matter or other potential contaminants are effectively kept at bay, ensuring sterile conditions where necessary. The installation and maintenance of elastic bellow covers are streamlined processes that further bolster their appeal. Requiring minimal tools and technical knowledge, these covers can be promptly fitted and replaced, minimizing downtime and ensuring that industrial operations continue with little interruption. Routine inspections and maintenance are recommended to detect any signs of wear or damage that could compromise the protection offered by the covers. The global market for elastic bellow covers is expanding, driven by technological advancements and increased industrialization worldwide. As businesses strive for higher efficiency, productivity, and reduced downtimes, the demand for reliable protective solutions like elastic bellow covers is expected to grow. In conclusion, elastic bellow covers are indispensable assets in safeguarding machinery and optimizing performance across diverse industries. Their flexible, durable, and adaptable characteristics meet the rigorous demands of modern industrial applications. By selecting the appropriate elastic bellow cover tailored to specific operational needs, industries can ensure product protection, operational efficiency, and long-term reliability. Leveraging expert support in choosing and maintaining these covers further enhances their effectiveness, establishing them as a cornerstone of industrial equipment protection strategies.

Elastic bellow covers also play a pivotal role in maintaining clean and hygienic environments, particularly in the food processing and medical industries. In these sectors, safeguarding processes from contamination is not only a regulatory requirement but also essential for product quality and safety. Elastic bellow covers ensure that particulate matter or other potential contaminants are effectively kept at bay, ensuring sterile conditions where necessary. The installation and maintenance of elastic bellow covers are streamlined processes that further bolster their appeal. Requiring minimal tools and technical knowledge, these covers can be promptly fitted and replaced, minimizing downtime and ensuring that industrial operations continue with little interruption. Routine inspections and maintenance are recommended to detect any signs of wear or damage that could compromise the protection offered by the covers. The global market for elastic bellow covers is expanding, driven by technological advancements and increased industrialization worldwide. As businesses strive for higher efficiency, productivity, and reduced downtimes, the demand for reliable protective solutions like elastic bellow covers is expected to grow. In conclusion, elastic bellow covers are indispensable assets in safeguarding machinery and optimizing performance across diverse industries. Their flexible, durable, and adaptable characteristics meet the rigorous demands of modern industrial applications. By selecting the appropriate elastic bellow cover tailored to specific operational needs, industries can ensure product protection, operational efficiency, and long-term reliability. Leveraging expert support in choosing and maintaining these covers further enhances their effectiveness, establishing them as a cornerstone of industrial equipment protection strategies.