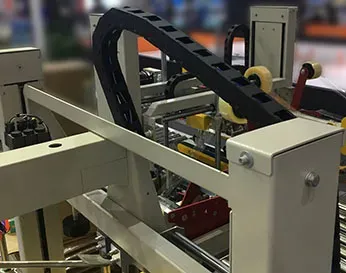

electrical cable chain

Understanding Electrical Cable Chains Structure and Function

Electrical cable chains, also known as drag chains or cable carriers, are essential components in various industrial applications. These chains provide a management system for electrical cables and hoses, protecting them from wear and tear while allowing for controlled movement. This article explores the structure, function, and benefits of electrical cable chains in modern industry.

At their core, cable chains are designed to guide and carry electrical cables and hoses along a designated path. They consist of a series of interconnected links, which create a flexible and durable enclosure for the cables. Typically made from materials like plastic or metal, these chains can withstand harsh environmental conditions, making them suitable for applications in manufacturing, automation, and robotics.

The primary function of an electrical cable chain is to protect cables and hoses from damage caused by repeated movements. In dynamic environments, such as robotic arms or conveyor belts, cables are subject to bending, twisting, and abrasion. Over time, such stress can lead to cable failures, which can disrupt operations and result in costly downtime. Cable chains mitigate this risk by keeping cables organized and reducing the likelihood of tangling or pinching.

electrical cable chain

One of the significant advantages of using cable chains is their versatility. They come in various sizes, shapes, and materials to accommodate different types of cables and industrial requirements. For instance, some chains feature additional compartments for air or fluid hoses, making them ideal for applications that require multiple types of connections. Furthermore, cable chains can be configured in straight lines, curves, and even spirals, offering flexibility in layout design.

Installation of cable chains is relatively straightforward, contributing to their popularity among engineers and designers. They can be mounted horizontally, vertically, or even overhead, which helps to save space in a production environment. The ease of installation also means that they can be integrated into existing systems without substantial modifications.

Additionally, many modern cable chains are designed with maintenance in mind. They often include features such as easy access points for cable installation and replacement. This design consideration can significantly reduce the time and labor costs associated with performing maintenance work.

In summary, electrical cable chains play a pivotal role in protecting and managing cables and hoses in various industrial applications. Their structure, designed for flexibility and strength, allows them to endure the rigors of dynamic environments. With their protective capabilities, versatility, and ease of installation, cable chains are indispensable tools in optimizing operational efficiency and enhancing equipment lifespan. As industries continue to evolve, the significance of cable management systems like electrical cable chains will only increase, further underscoring their importance in contemporary automation and engineering practices.