Understanding the Benefits and Applications of Electrical Cable Chains in Modern Industries

Understanding Electrical Cable Chains An Essential Component in Modern Machinery

Electrical cable chains, also known as cable carriers or drag chains, play a crucial role in various industrial applications, particularly in environments where moving machinery relies on complex systems of electrical cables and hoses. These chains are designed to protect, guide, and manage the movement of cables, ensuring that they function efficiently and remain undamaged during operation. In this article, we will explore the importance of electrical cable chains, their applications, and the benefits they offer.

What Are Electrical Cable Chains?

Electrical cable chains are mechanical structures that consist of multiple interconnected links, which form a flexible conduit for cables and hoses. The links are designed to provide support while allowing for free movement, making them ideal for applications involving repetitive motion. These chains can accommodate a variety of cables, including power, data, and pneumatic lines, organizing them neatly and preventing tangling or wear.

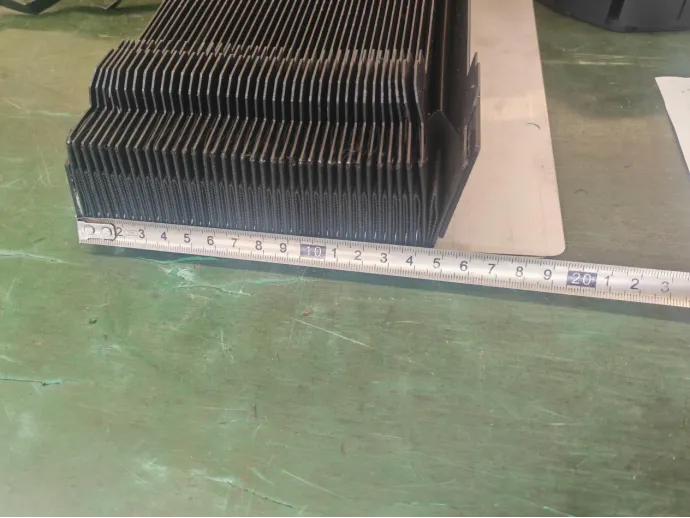

The design of cable chains varies based on the specific needs of the application. Standard models may be open or closed, and they can be manufactured from materials such as plastic, steel, or aluminum. The choice of material depends on factors such as weight, strength, environment, and load capacity.

Applications of Electrical Cable Chains

Electrical cable chains are widely used in numerous industries, from manufacturing to entertainment

. Here are a few notable applications1. Industrial Automation In automated manufacturing systems, cable chains are essential for guiding and protecting the cables connected to robotic arms, conveyor systems, and CNC machines. They ensure smooth operation by preventing cable snagging and allowing for unrestricted movement.

2. Cranes and Lifting Equipment Cable chains are utilized in cranes and lifting equipment to manage the extensive cabling required for operation. They enhance the longevity of cables by minimizing abrasion and reducing mechanical stress during lifting operations.

3. Medical Equipment In medical environments, where equipment mobility is vital, cable chains support medical devices such as MRI machines and surgical robots. They help maintain cleanliness and safety by organizing cables in a way that minimizes the risk of tripping hazards.

electrical cable chain

4. Entertainment Industry In theaters and broadcast studios, cable chains are used to manage cables for lighting rigs and camera systems. They offer flexibility and ease of movement, allowing for dynamic setups in various production scenarios.

Benefits of Using Electrical Cable Chains

The incorporation of electrical cable chains into machinery brings multiple benefits

- Protection One of the primary advantages is the protection they offer to cables and hoses. By housing them within a structured chain, they are shielded from external damage, wear, and tear, prolonging their lifespan.

- Organization Cable chains help maintain order in environments with extensive cabling. Proper organization reduces clutter, making maintenance easier and improving safety by minimizing tripping hazards.

- Enhanced Mobility Electrical cable chains facilitate smoother movements in machinery. This is particularly important in applications requiring high precision and agility, such as automation and robotics.

- Reduced Downtime By preventing cable damage, electrical cable chains help minimize equipment downtime caused by repairs or replacements. This translates to increased productivity and efficiency in various industrial processes.

Conclusion

As industries continue to evolve and embrace automation, the role of electrical cable chains becomes increasingly significant. They are not only essential for the efficiency and functionality of modern machinery but also contribute to safety and longevity. Understanding their importance can help businesses make informed decisions when designing and maintaining their systems, ultimately leading to sustained operational success. Adopting these innovative solutions can result in smoother operations, reduced costs, and enhanced overall productivity.