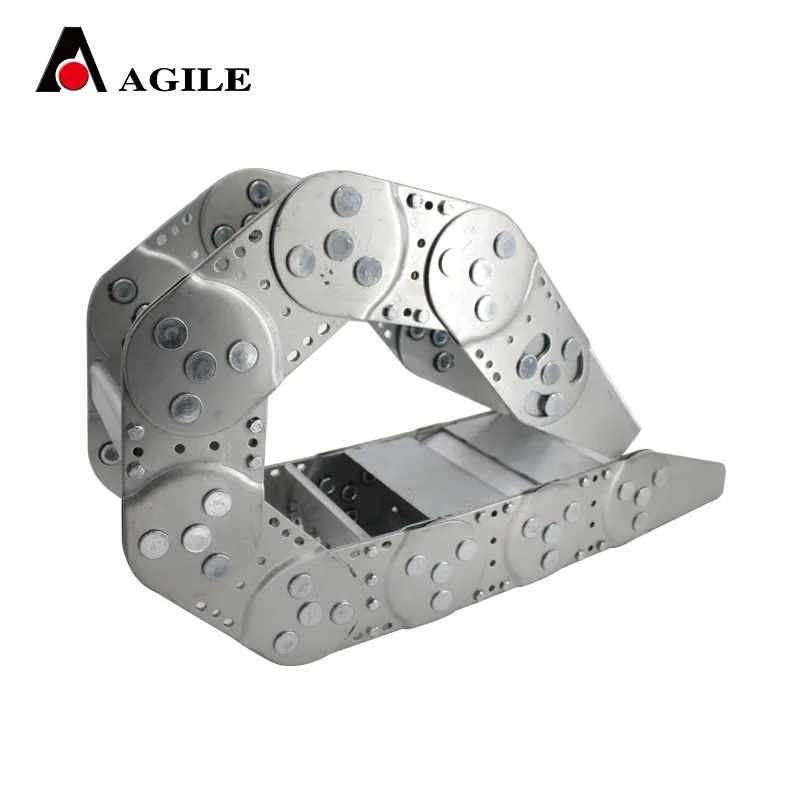

electrical cable track

Navigating the world of electrical cable tracks can be a daunting task, especially for those who seek to ensure the utmost in safety, efficiency, and cost-effectiveness for their projects. Having worked extensively in the field of electrical engineering and project management, I can share firsthand insights into why focusing on the quality and suitability of electrical cable tracks is essential for any construction or industrial automation project.

Trusting anecdotal evidence from peers or industry reviews often serves as an additional verification layer. In my experience, working directly with suppliers who offer transparent breakdowns of product testing data can provide invaluable peace of mind. This becomes particularly relevant when considering the diverse environments cable tracks might operate in—from extreme temperatures in industrial freezers to high moisture levels in marine applications. Finally, the longevity and dependability of your electrical installations rely heavily not just on the cable track itself but also on its installation. Expert installation services provide the assurance that the tracks will function optimally over time, honoring warranty conditions and service agreements. Poor installation practices can negate even the highest quality product advantages, leading to mishaps and financial setbacks. In conclusion, electrical cable tracks play an indisputable role in ensuring operational excellence and safety across multiple industries. Whether you're involved in heavy-duty industrial applications or pursuing lean automation processes, these tracks provide the backbone of your electrical framework. The key lies in selecting the right type and quality while relying on professional advice for installation. Balancing these factors ensures that your systems remain robust, efficient, and poised for future challenges, underpinning your project's overall success.

Trusting anecdotal evidence from peers or industry reviews often serves as an additional verification layer. In my experience, working directly with suppliers who offer transparent breakdowns of product testing data can provide invaluable peace of mind. This becomes particularly relevant when considering the diverse environments cable tracks might operate in—from extreme temperatures in industrial freezers to high moisture levels in marine applications. Finally, the longevity and dependability of your electrical installations rely heavily not just on the cable track itself but also on its installation. Expert installation services provide the assurance that the tracks will function optimally over time, honoring warranty conditions and service agreements. Poor installation practices can negate even the highest quality product advantages, leading to mishaps and financial setbacks. In conclusion, electrical cable tracks play an indisputable role in ensuring operational excellence and safety across multiple industries. Whether you're involved in heavy-duty industrial applications or pursuing lean automation processes, these tracks provide the backbone of your electrical framework. The key lies in selecting the right type and quality while relying on professional advice for installation. Balancing these factors ensures that your systems remain robust, efficient, and poised for future challenges, underpinning your project's overall success.