Energy Chain Cable Solutions for Efficient Power Transmission in Industrial Applications

Understanding Energy Chain Cables A Comprehensive Overview

In today’s rapidly advancing technological world, the demand for efficient, reliable, and flexible solutions for powering machinery and equipment has never been more critical. Among these solutions, energy chain cables play a pivotal role, particularly in environments where movement and flexibility are essential. This article delves into the concept of energy chain cables, their applications, advantages, and factors to consider when choosing the right type for specific needs.

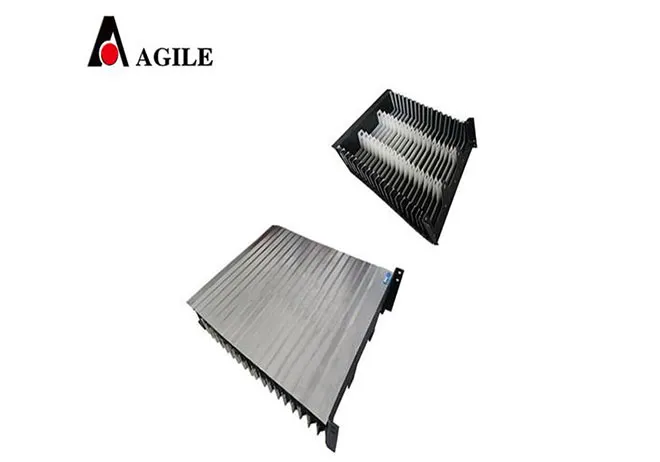

Energy chain cables, also known as drag chains or cable carriers, are designed to protect and manage power, control, and data cables in applications involving significant movement. These cables are typically housed within a flexible plastic or metal chain that allows them to move freely while minimizing wear and tear. The primary function of an energy chain is to provide a secure means of cable management while ensuring that the cables remain organized, intact, and free from tangling.

One of the notable applications of energy chain cables is in automated machinery and robotics, where precision and flexibility are crucial

. As machines move along predefined paths, energy chains help guide and protect the cables that provide power or communication to the moving parts. This feature not only prolongs the life of the cables by reducing friction and strain but also enhances the overall efficiency and performance of the machinery.energy chain cable

The advantages of using energy chain cables are manifold. Firstly, they offer protection against abrasion, crushing, and other environmental factors that could damage the cables. Secondly, energy chains provide excellent flexibility, allowing for complex movement patterns without compromising the integrity of the cables. Moreover, they facilitate maintenance as cables can be easily replaced or repaired without dismantling the entire system.

When selecting energy chain cables, several factors must be considered. The type of application, including the distance, movement, and load, will influence the choice of the energy chain and the specific cables it will carry. Additionally, the environmental conditions, such as temperature variations, exposure to chemicals, or outdoor usage, should also dictate the material and design of the energy chain. It is also essential to evaluate the maximum bending radius, chain length, and load capacity to ensure optimal performance.

In conclusion, energy chain cables are an indispensable component in a variety of modern applications, particularly where movement and flexibility are essential. Their ability to protect and manage cables effectively makes them invaluable in numerous industries, from manufacturing to robotics. By understanding the intricacies involved in choosing and implementing energy chain cables, businesses can enhance their operational efficiency, reduce downtime, and extend the lifespan of their machinery and equipment. As technology continues to evolve, the importance of reliable and efficient cable management solutions will only grow, further solidifying the role of energy chain cables within the industrial landscape.