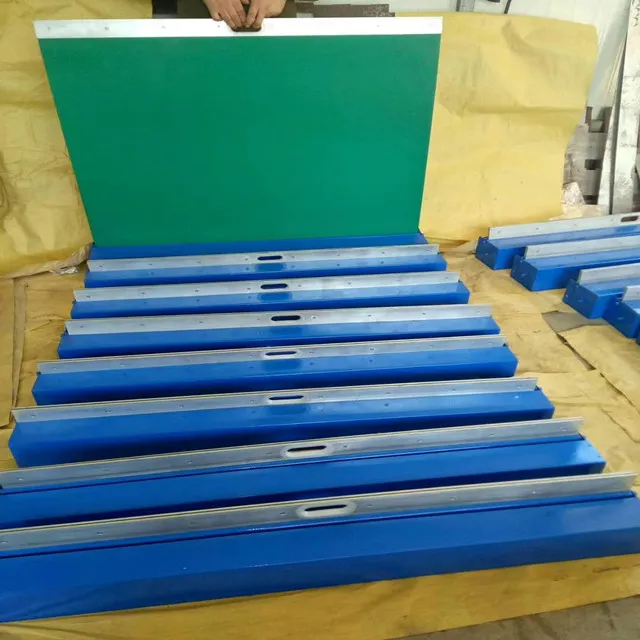

small cable track

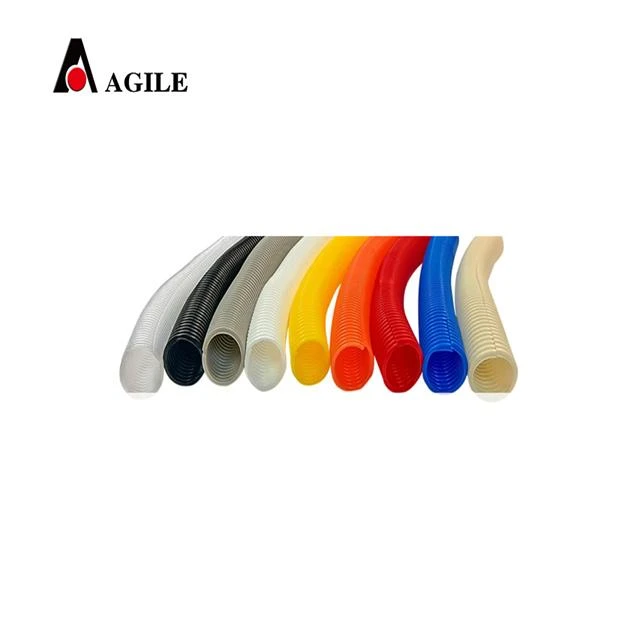

In the dynamic landscape of modern technology, flex cable tracks have emerged as a critical component in diverse industries, offering unparalleled flexibility and durability. These tracks serve as the lifeline for electronic and mechanical systems, ensuring seamless connectivity and movement across complex machinery and devices. Through firsthand experience and a deep understanding of engineering principles, this article delves into the intricacies, applications, and advantages of flex cable tracks, presenting an authoritative viewpoint that engineers and decision-makers can trust.

The credibility of flex cable track solutions is anchored in comprehensive testing and adherence to international standards. Trusted manufacturers prioritize rigorous assessments, ensuring each product meets the stringent demands of industry certifications like ISO, RoHS, and UL. The peace of mind that comes from knowing a product is built to the highest standards cannot be overstated. As a testament to trust, these certifications validate the product's safety, environmental compliance, and reliability under even the most demanding conditions. In practice, embracing the advancements in flex cable technology entails more than just acquiring components; it involves partnering with suppliers who offer ongoing support and insights grounded in extensive industry experience. Through collaboration with knowledgeable providers, companies gain access to innovative solutions tailored to their unique challenges, bolstering both expertise and outcome quality. Ultimately, the evolution of flex cable tracks showcases a commitment to efficiency, reliability, and endurance. Whether it's enabling robotic limbs with precision-guided movements, safeguarding vital hospital equipment, or empowering space exploration missions, these tracks serve as foundational elements in the pursuit of technological excellence. Understanding their profound impact through direct experience equips industry leaders and engineers with the expertise necessary to navigate today's engineering challenges while preparing for tomorrow’s innovations. In conclusion, flex cable tracks are much more than simple components; they are integral to the pursuit of technological advancement across numerous industries. By prioritizing material selection, customization, and quality assurance, manufacturers and engineers alike harness their full potential, cementing their status as indispensable assets in the digital age.

The credibility of flex cable track solutions is anchored in comprehensive testing and adherence to international standards. Trusted manufacturers prioritize rigorous assessments, ensuring each product meets the stringent demands of industry certifications like ISO, RoHS, and UL. The peace of mind that comes from knowing a product is built to the highest standards cannot be overstated. As a testament to trust, these certifications validate the product's safety, environmental compliance, and reliability under even the most demanding conditions. In practice, embracing the advancements in flex cable technology entails more than just acquiring components; it involves partnering with suppliers who offer ongoing support and insights grounded in extensive industry experience. Through collaboration with knowledgeable providers, companies gain access to innovative solutions tailored to their unique challenges, bolstering both expertise and outcome quality. Ultimately, the evolution of flex cable tracks showcases a commitment to efficiency, reliability, and endurance. Whether it's enabling robotic limbs with precision-guided movements, safeguarding vital hospital equipment, or empowering space exploration missions, these tracks serve as foundational elements in the pursuit of technological excellence. Understanding their profound impact through direct experience equips industry leaders and engineers with the expertise necessary to navigate today's engineering challenges while preparing for tomorrow’s innovations. In conclusion, flex cable tracks are much more than simple components; they are integral to the pursuit of technological advancement across numerous industries. By prioritizing material selection, customization, and quality assurance, manufacturers and engineers alike harness their full potential, cementing their status as indispensable assets in the digital age.