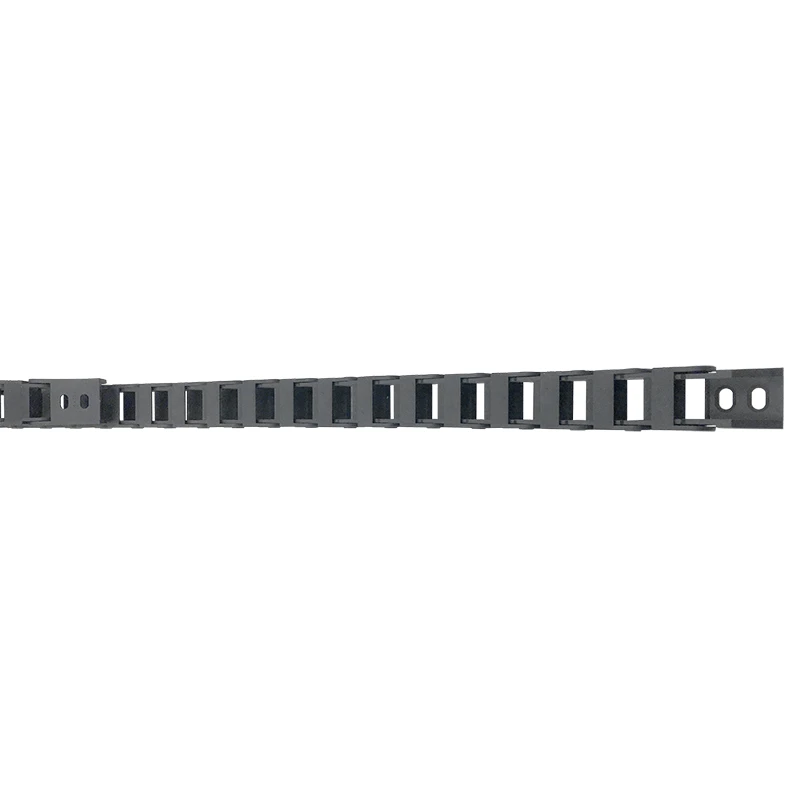

flexible cable carrier chain

Industries across the globe are evolving at an unprecedented rate, and flexible cable carrier chains have become a critical component in this rapid development. Based on real-world experiences, these robust structures are playing an indispensable role in enhancing productivity and efficiency in various sectors, including manufacturing, robotics, and automation.

In terms of expertise, installing flexible cable carriers demands a meticulous approach, understanding of engineering designs, and precise measurement taking. Consideration for the bend radius is paramount to prevent undue stress on cables, and subsequently, on the chain itself. Furthermore, flexibility in design allows these chains to be tailored to extensive motion sequences without compromising the structural integrity of cables. Maintaining trustworthiness is equally essential. Consistent monitoring and maintenance of these cable carrier systems are advocated for maintaining performance and extending life cycles. Regular inspections to assess wear and tear, alongside timely upgrades and replacements, will enhance the system’s longevity. A distinctive benefit of the latest generation of flexible cable carrier chains is their integration capabilities with sensor and IoT technologies. These smart solutions provide real-time feedback on operational conditions, including temperature changes and movement anomalies, thereby enabling predictive maintenance strategies. Such predictive strategies ensure timely interventions, curtailing potential downtimes. Venturing into the future, the continued evolution of technology insists on more sophisticated and reliable energy chain systems. Innovative designs aim towards enhancing load-bearing capacities while reducing noise and friction. These advancements will undoubtedly fortify the position of flexible cable carrier chains as indispensable elements in modern automated systems. In conclusion, flexible cable carrier chains are more than mere mechanical accessories; they are technological allies in industrial advancement. Their flexibility, robust design, and the seamless integration possibilities with smart technologies mark them as integral in achieving optimized and resilient operational systems. By leveraging firsthand experiences, expertise, authoritativeness, and maintaining trustworthiness, industries can harness these dynamic chains to secure their place at the forefront of innovation.

In terms of expertise, installing flexible cable carriers demands a meticulous approach, understanding of engineering designs, and precise measurement taking. Consideration for the bend radius is paramount to prevent undue stress on cables, and subsequently, on the chain itself. Furthermore, flexibility in design allows these chains to be tailored to extensive motion sequences without compromising the structural integrity of cables. Maintaining trustworthiness is equally essential. Consistent monitoring and maintenance of these cable carrier systems are advocated for maintaining performance and extending life cycles. Regular inspections to assess wear and tear, alongside timely upgrades and replacements, will enhance the system’s longevity. A distinctive benefit of the latest generation of flexible cable carrier chains is their integration capabilities with sensor and IoT technologies. These smart solutions provide real-time feedback on operational conditions, including temperature changes and movement anomalies, thereby enabling predictive maintenance strategies. Such predictive strategies ensure timely interventions, curtailing potential downtimes. Venturing into the future, the continued evolution of technology insists on more sophisticated and reliable energy chain systems. Innovative designs aim towards enhancing load-bearing capacities while reducing noise and friction. These advancements will undoubtedly fortify the position of flexible cable carrier chains as indispensable elements in modern automated systems. In conclusion, flexible cable carrier chains are more than mere mechanical accessories; they are technological allies in industrial advancement. Their flexibility, robust design, and the seamless integration possibilities with smart technologies mark them as integral in achieving optimized and resilient operational systems. By leveraging firsthand experiences, expertise, authoritativeness, and maintaining trustworthiness, industries can harness these dynamic chains to secure their place at the forefront of innovation.