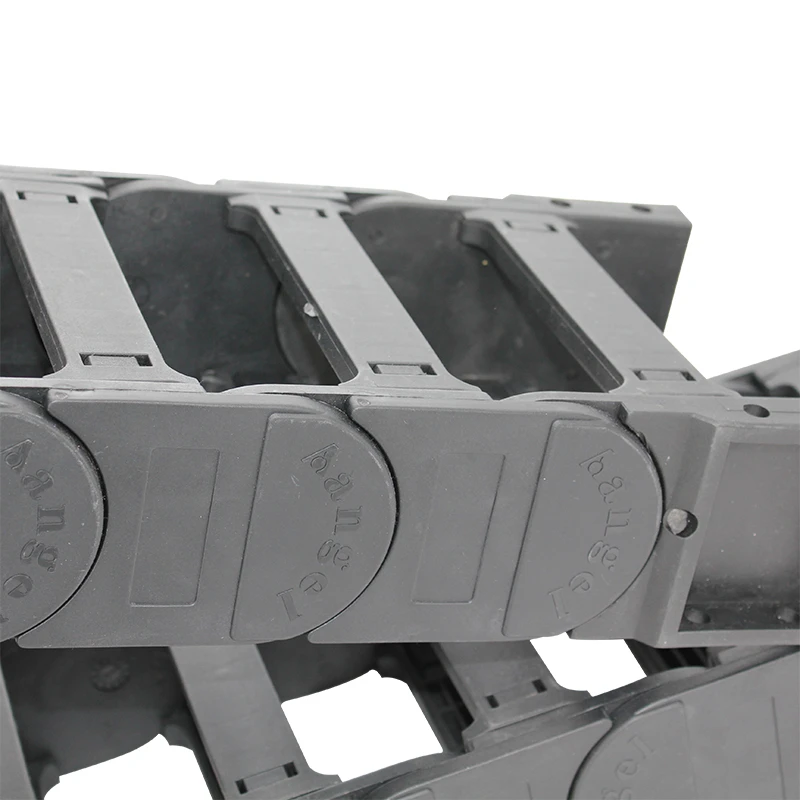

flexible cable carrier chain

Flexible cable carrier chains play an integral role in modern industrial and automation systems, ensuring the safe and efficient management of cables and hoses. These unsung heroes behind the scenes are pivotal for maintaining the functionality and longevity of the machinery they support. In delving deep into their significance, it becomes evident how their design and versatility enhance productivity and reduce downtime.

The implementation of flexible cable carrier chains also facilitates modular design in industrial systems. This modularity is crucial for scaling operations as businesses grow or diversify their product offerings. With the ability to quickly reconfigure machinery setups without extensive rewiring, flexible chains offer a cost-effective solution for maintaining production agility. In terms of authority and trustworthiness, firms specializing in flexible cable carrier chains often collaborate closely with original equipment manufacturers (OEMs) to tailor products specific to industry requirements. Such collaborations ensure that the carriers fulfill not only the mechanical demands but also adhere to rigorous safety and industry standards. By sourcing carriers from reputable manufacturers, companies can assure themselves of a reliable supply chain and expert support in system integration. Industry experts frequently emphasize the importance of regular inspections and maintenance of flexible cable carrier chains. Doing so helps in early detection of wear and tear, especially in high-stress applications that demand continuous operation. Preventative maintenance ensures that carrier systems function optimally, safeguarding against potential system breakdowns that can result in significant operational disruptions. As industrial automation evolves, flexible cable carrier chains will continue to advance, incorporating smart technologies such as real-time monitoring and IoT capabilities. These innovations promise to enhance predictability in system upkeep, reduce manual inspection times, and further align cable management systems with smart factory objectives. In conclusion, the utility of flexible cable carrier chains extends far beyond mere cable management. They are a critical component in modern industrial and automation landscapes. By procuring high-quality chains from established manufacturers and prioritizing regular maintenance, companies can enhance their operational reliability, exemplifying a commitment to excellence within their production methodologies.

The implementation of flexible cable carrier chains also facilitates modular design in industrial systems. This modularity is crucial for scaling operations as businesses grow or diversify their product offerings. With the ability to quickly reconfigure machinery setups without extensive rewiring, flexible chains offer a cost-effective solution for maintaining production agility. In terms of authority and trustworthiness, firms specializing in flexible cable carrier chains often collaborate closely with original equipment manufacturers (OEMs) to tailor products specific to industry requirements. Such collaborations ensure that the carriers fulfill not only the mechanical demands but also adhere to rigorous safety and industry standards. By sourcing carriers from reputable manufacturers, companies can assure themselves of a reliable supply chain and expert support in system integration. Industry experts frequently emphasize the importance of regular inspections and maintenance of flexible cable carrier chains. Doing so helps in early detection of wear and tear, especially in high-stress applications that demand continuous operation. Preventative maintenance ensures that carrier systems function optimally, safeguarding against potential system breakdowns that can result in significant operational disruptions. As industrial automation evolves, flexible cable carrier chains will continue to advance, incorporating smart technologies such as real-time monitoring and IoT capabilities. These innovations promise to enhance predictability in system upkeep, reduce manual inspection times, and further align cable management systems with smart factory objectives. In conclusion, the utility of flexible cable carrier chains extends far beyond mere cable management. They are a critical component in modern industrial and automation landscapes. By procuring high-quality chains from established manufacturers and prioritizing regular maintenance, companies can enhance their operational reliability, exemplifying a commitment to excellence within their production methodologies.