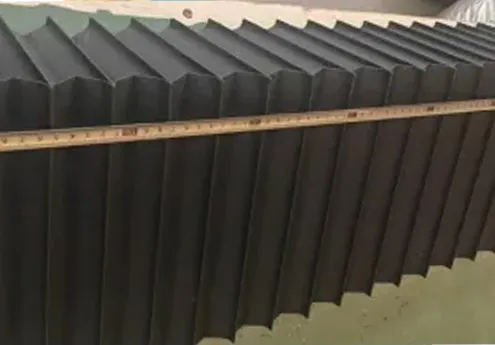

flexible cable chain

Flexible cable chains, also known as cable carriers or drag chains, are pivotal components within various industrial and automation applications. Their primary function is to house and guide electrical cables or hydraulic and pneumatic hoses connected to moving automated machines. The correct selection and maintenance of these cable chains dramatically influence the efficiency, safety, and longevity of the associated systems they serve. Being underappreciated, yet utterly crucial, understanding these devices can significantly optimize your operations and reduce maintenance costs.

In terms of authority and trust, industry leaders such as igus, Tsubaki Kabelschlepp, and Brevetti Stendalto have set high benchmarks in cable chain innovation and reliability. Their expertise has cemented their reputation, making them the go-to choice for industries ranging from aerospace to food processing. Another key element is customization. Companies often underestimate the impact of tailor-made solutions that flexible cable chain manufacturers can provide. By adapting the chain dimensions, materials, or features to the specific needs of a project, businesses can achieve enhanced operational efficiency and reliability. An expert suggestion would be to engage directly with manufacturers for advice on customization options that would best fit your particular use case. It's important to highlight the hidden cost benefits associated with the correct application of flexible cable chains. Properly implemented, they can significantly reduce wear and tear on cables and hoses, thus extending their life span and reducing replacement frequency. Additionally, by preventing cable failures, these chains can help avoid potential production halts, thereby safeguarding revenue streams. In conclusion, as an SEO-optimized narrative on flexible cable chains reveals, these often-overlooked components play a foundational role in modern mechanized industries. Their proper application demands a blend of experiential insight and expert guidance, alongside authoritative resources and sustained maintenance efforts to ensure operational excellence and cost-efficiency. By integrating these practices, and fostering trusted relationships with reputable suppliers, companies can navigate the complexities of industrial automation with greater confidence and competence.

In terms of authority and trust, industry leaders such as igus, Tsubaki Kabelschlepp, and Brevetti Stendalto have set high benchmarks in cable chain innovation and reliability. Their expertise has cemented their reputation, making them the go-to choice for industries ranging from aerospace to food processing. Another key element is customization. Companies often underestimate the impact of tailor-made solutions that flexible cable chain manufacturers can provide. By adapting the chain dimensions, materials, or features to the specific needs of a project, businesses can achieve enhanced operational efficiency and reliability. An expert suggestion would be to engage directly with manufacturers for advice on customization options that would best fit your particular use case. It's important to highlight the hidden cost benefits associated with the correct application of flexible cable chains. Properly implemented, they can significantly reduce wear and tear on cables and hoses, thus extending their life span and reducing replacement frequency. Additionally, by preventing cable failures, these chains can help avoid potential production halts, thereby safeguarding revenue streams. In conclusion, as an SEO-optimized narrative on flexible cable chains reveals, these often-overlooked components play a foundational role in modern mechanized industries. Their proper application demands a blend of experiential insight and expert guidance, alongside authoritative resources and sustained maintenance efforts to ensure operational excellence and cost-efficiency. By integrating these practices, and fostering trusted relationships with reputable suppliers, companies can navigate the complexities of industrial automation with greater confidence and competence.