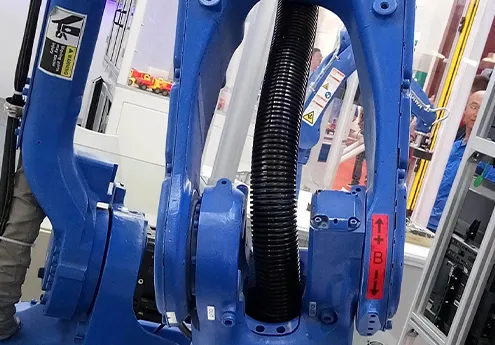

flexible cable chain

Flexible cable chains, an often-overlooked element in cable management, have become crucial components in many industries. From automotive assembly lines to high-tech robotic arms, these cable carriers play a pivotal role in ensuring seamless operation and optimal performance. Understanding the nuances of flexible cable chains can greatly enhance system reliability and prolong equipment lifespan.

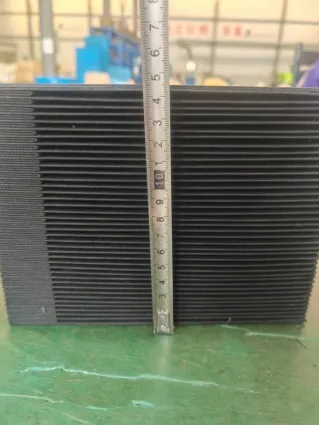

Durability and material composition are other critical aspects to consider. High-quality cable chains are often made of materials like reinforced nylon or stainless steel, offering excellent resistance to wear, impact, and chemical exposure. These materials not only provide protection but also contribute to the longevity and reliability of the system. The choice of material should align with the specific environmental conditions the chain will face, ensuring optimal performance and reduced maintenance costs. Authoritativeness within the flexible cable chain segment requires recognition of leading manufacturers and distributors who adhere to industry standards and certifications. Brands that also offer customized solutions demonstrate a deep understanding of the diverse needs across industries and establish themselves as trusted partners in engineering solutions. It is prudent to engage with suppliers who offer technical support and comprehensive guidelines for installation and maintenance, reflecting their commitment to quality and customer success. Implementing flexible cable chains is not merely about installation; it involves designing a reliable system. Maintenance plays a vital role in upholding the chain's performance and safety standards over time. Routine inspections to identify wear points or distortions can mitigate potential failures. Establishing a preventive maintenance schedule tailored to the application can significantly enhance the trustworthiness of these systems, preventing unforeseen breakdowns and ensuring uninterrupted operation. In conclusion, flexible cable chains stand as integral components in modern dynamic applications, extending beyond their fundamental purpose of guiding cables. They ensure enhanced system efficiency by protecting critical connections and adapting to a multitude of environments and movements. Expertise in selecting the appropriate chain, combined with adherence to rigorous maintenance strategies and partnerships with authoritative suppliers, can secure the long-term success and reliability of any application utilizing these essential systems.

Durability and material composition are other critical aspects to consider. High-quality cable chains are often made of materials like reinforced nylon or stainless steel, offering excellent resistance to wear, impact, and chemical exposure. These materials not only provide protection but also contribute to the longevity and reliability of the system. The choice of material should align with the specific environmental conditions the chain will face, ensuring optimal performance and reduced maintenance costs. Authoritativeness within the flexible cable chain segment requires recognition of leading manufacturers and distributors who adhere to industry standards and certifications. Brands that also offer customized solutions demonstrate a deep understanding of the diverse needs across industries and establish themselves as trusted partners in engineering solutions. It is prudent to engage with suppliers who offer technical support and comprehensive guidelines for installation and maintenance, reflecting their commitment to quality and customer success. Implementing flexible cable chains is not merely about installation; it involves designing a reliable system. Maintenance plays a vital role in upholding the chain's performance and safety standards over time. Routine inspections to identify wear points or distortions can mitigate potential failures. Establishing a preventive maintenance schedule tailored to the application can significantly enhance the trustworthiness of these systems, preventing unforeseen breakdowns and ensuring uninterrupted operation. In conclusion, flexible cable chains stand as integral components in modern dynamic applications, extending beyond their fundamental purpose of guiding cables. They ensure enhanced system efficiency by protecting critical connections and adapting to a multitude of environments and movements. Expertise in selecting the appropriate chain, combined with adherence to rigorous maintenance strategies and partnerships with authoritative suppliers, can secure the long-term success and reliability of any application utilizing these essential systems.