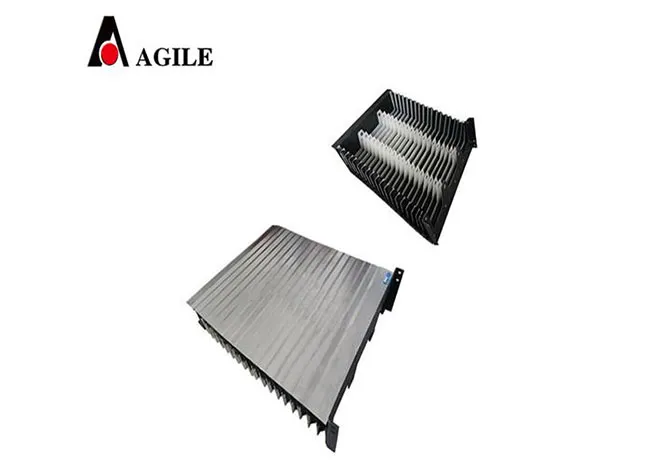

hinge chip conveyor

Hinge chip conveyors revolutionize the way industries handle and manage chips and swarf accumulation during machining processes. At the crossroads of efficiency and technological innovation, these conveyors serve a vital role in maintaining cleanliness and promoting productivity in environments where precision is paramount. Delving deeper into the hinge chip conveyor reveals a plethora of benefits and distinct features that cater to the demanding needs of modern manufacturing facilities.

An often-overlooked benefit of hinge chip conveyors is their contribution to improving workplace safety and cleanliness. Chips left unmanaged can present hazardous conditions, such as slipping risks and potential harm from sharp edges. By efficiently removing chips from the work area, these conveyors reduce such risks, creating a safer environment for workers. Furthermore, by maintaining workplace tidiness, they help uphold industry standards and company regulations regarding occupational safety and health. In terms of authority and trustworthiness, hinge chip conveyors underscore their relevance through compliance with global manufacturing standards and certifications. They are designed to exceed regulatory requirements, showcasing their readiness and suitability for deployment in high-stakes manufacturing environments. Trusted manufacturers of these conveyors provide not just a product but a comprehensive solution backed by extensive research, development, and real-world testing. They often involve field experts to ensure the conveyor designs meet the stringent demands of modern-day industries. Lastly, choosing the right hinge chip conveyor requires an understanding of the specific needs of your manufacturing process. Engage with manufacturers who offer consultations and custom solutions, ensuring they comprehend your unique challenges and objectives. Leading suppliers will provide detailed product information, specifications, and case studies that reflect their expertise and commitment to customer satisfaction. Through transparency and client engagement, the best manufacturers foster a reliable partnership, enhancing trust and confidence in their products. In conclusion, hinge chip conveyors are more than just mechanical systems; they are integral components of modern manufacturing processes, offering enhanced efficiency, safety, and operational longevity. With continued advancements in technology and a persistent emphasis on manufacturing excellence, these conveyors will undoubtedly remain pivotal in addressing the ever-evolving demands for precision, cleanliness, and productivity in industrial environments.

An often-overlooked benefit of hinge chip conveyors is their contribution to improving workplace safety and cleanliness. Chips left unmanaged can present hazardous conditions, such as slipping risks and potential harm from sharp edges. By efficiently removing chips from the work area, these conveyors reduce such risks, creating a safer environment for workers. Furthermore, by maintaining workplace tidiness, they help uphold industry standards and company regulations regarding occupational safety and health. In terms of authority and trustworthiness, hinge chip conveyors underscore their relevance through compliance with global manufacturing standards and certifications. They are designed to exceed regulatory requirements, showcasing their readiness and suitability for deployment in high-stakes manufacturing environments. Trusted manufacturers of these conveyors provide not just a product but a comprehensive solution backed by extensive research, development, and real-world testing. They often involve field experts to ensure the conveyor designs meet the stringent demands of modern-day industries. Lastly, choosing the right hinge chip conveyor requires an understanding of the specific needs of your manufacturing process. Engage with manufacturers who offer consultations and custom solutions, ensuring they comprehend your unique challenges and objectives. Leading suppliers will provide detailed product information, specifications, and case studies that reflect their expertise and commitment to customer satisfaction. Through transparency and client engagement, the best manufacturers foster a reliable partnership, enhancing trust and confidence in their products. In conclusion, hinge chip conveyors are more than just mechanical systems; they are integral components of modern manufacturing processes, offering enhanced efficiency, safety, and operational longevity. With continued advancements in technology and a persistent emphasis on manufacturing excellence, these conveyors will undoubtedly remain pivotal in addressing the ever-evolving demands for precision, cleanliness, and productivity in industrial environments.