horizontal bellow cover

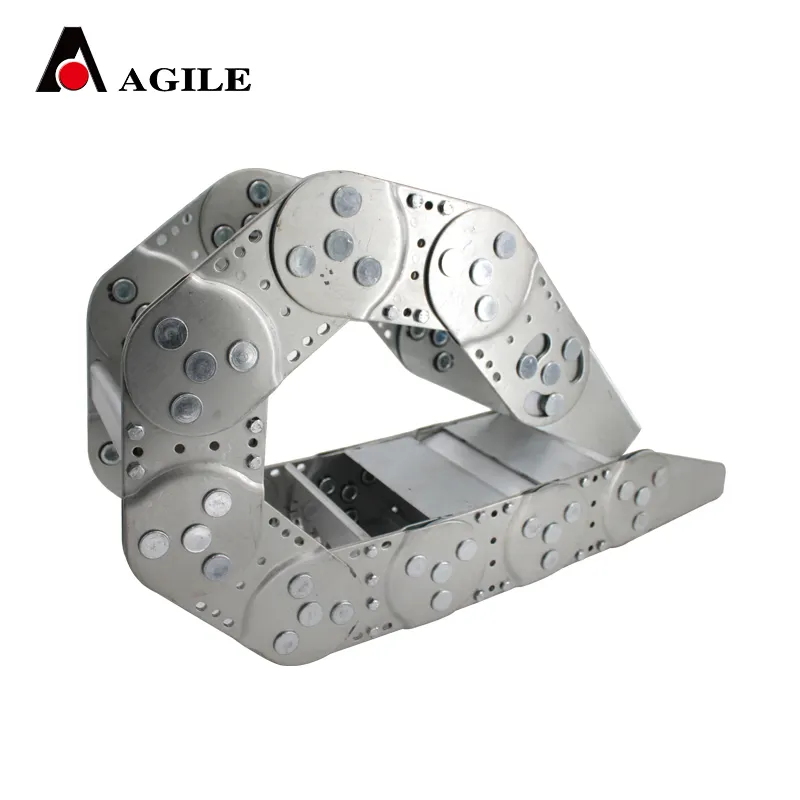

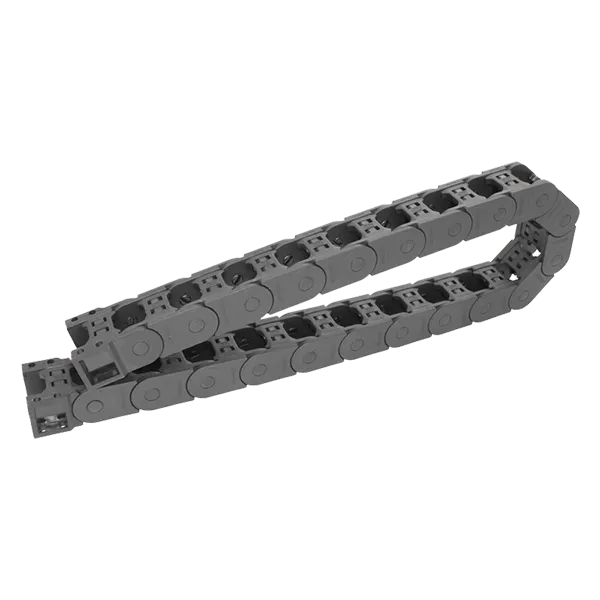

In the world of industrial applications, the seemingly small yet crucial component of horizontal bellow covers plays an unsung role in ensuring the efficient and safe operation of machinery. These covers, commonly employed to shield guideways and machine components from dust, debris, and other harmful elements, are indispensable in maintaining the longevity and functionality of industrial machines. Understanding the nuances of these components not only underscores their importance but also enhances selection criteria for various applications.

Authoritativeness in this space is marked by an in-depth understanding of the interplay between machinery and protective components. Industry leaders often collaborate with manufacturers of horizontal bellow covers during the design phase of new equipment to customize solutions that enhance machine efficiency and lifecycle. By integrating protective covers designed for optimal performance, these collaborations yield machinery that not only performs better but also lasts longer. Trustworthiness, a cornerstone of industry relationships, is built upon the dependable performance of these bellow covers. Companies must rely on suppliers who provide verifiable product testing outcomes that guarantee the cover's resilience against mechanical stress, environmental factors, and chemical resistance. Certifications and compliance with industry standards reinforce the trust customers place in these products, ensuring that they hold up under the pressures of diverse applications. In sum, the nuanced integration of horizontal bellow covers into industrial mechanisms marks an intersection of science, experience, and trust. It is this blend that not only safeguards high-value machinery but also propels industries toward greater efficiencies and reduced costs. Engineers and industrial planners are well-advised to invest in thorough evaluations and partnerships with seasoned manufacturers to procure bellow covers genuinely suited to their operational needs. By doing so, they fortify their equipment against the relentless demands of industrial environments, ensuring sustained performance and reliability.

Authoritativeness in this space is marked by an in-depth understanding of the interplay between machinery and protective components. Industry leaders often collaborate with manufacturers of horizontal bellow covers during the design phase of new equipment to customize solutions that enhance machine efficiency and lifecycle. By integrating protective covers designed for optimal performance, these collaborations yield machinery that not only performs better but also lasts longer. Trustworthiness, a cornerstone of industry relationships, is built upon the dependable performance of these bellow covers. Companies must rely on suppliers who provide verifiable product testing outcomes that guarantee the cover's resilience against mechanical stress, environmental factors, and chemical resistance. Certifications and compliance with industry standards reinforce the trust customers place in these products, ensuring that they hold up under the pressures of diverse applications. In sum, the nuanced integration of horizontal bellow covers into industrial mechanisms marks an intersection of science, experience, and trust. It is this blend that not only safeguards high-value machinery but also propels industries toward greater efficiencies and reduced costs. Engineers and industrial planners are well-advised to invest in thorough evaluations and partnerships with seasoned manufacturers to procure bellow covers genuinely suited to their operational needs. By doing so, they fortify their equipment against the relentless demands of industrial environments, ensuring sustained performance and reliability.