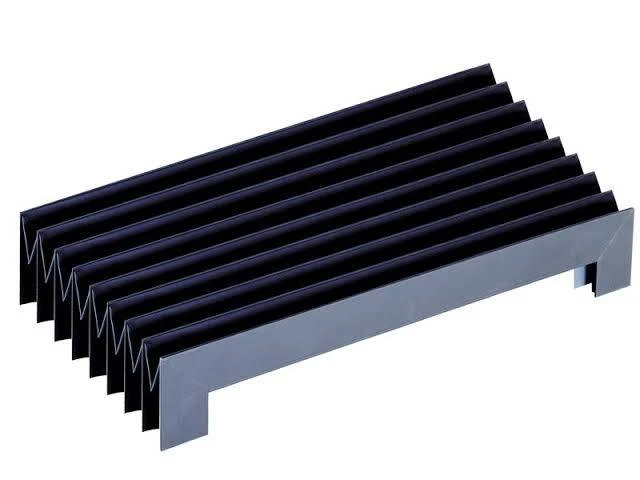

hydraulic hose drag chain

Selecting the right hydraulic hose drag chain is crucial for the optimal performance and longevity of hydraulic systems. With years of experience in fluid power management, I've witnessed how the right combination of components can significantly enhance machinery efficiency and reduce downtime.

Trustworthiness in the selection process comes from peer reviews and testimonials across industrial sectors. Real-world testing and feedback provide invaluable insights into product performance over time. Platforms where users share their experiences can be gold mines for identifying potential issues and solutions before making any procurement decisions. Installation and maintenance practices also significantly impact the effectiveness of a hydraulic hose drag chain. It’s essential to follow the manufacturer's guidelines for installation to prevent misalignment and slippage of the chain, which can otherwise lead to component fatigue. Regular maintenance checks, including inspection for wear and tear and testing of flexibility, ensure the drag chain remains in peak condition. Moreover, the integration of modern technologies in hydraulic hose drag chains presents exciting innovations. Features such as noise reduction technology, modular links for easy customization, and self-lubricating materials can provide added value to the hydraulic systems. Lastly, environmental considerations must be made when selecting a drag chain. Industrial processes now lean towards sustainable practices. Selecting chains made from recyclable materials not only supports environmental efforts but positions a company as a forward-thinking and responsible entity. In conclusion, the choice of a hydraulic hose drag chain requires a balanced consideration of material science, precise engineering, trusted manufacturing, and informed user feedback. By prioritizing these elements, businesses can enhance operational safety, efficiency, and sustainability, gaining a competitive edge in their respective fields. This informed decision-making process will ultimately establish a hydraulic system that stands the test of time, justifying its investment through reliable and safe performance.

Trustworthiness in the selection process comes from peer reviews and testimonials across industrial sectors. Real-world testing and feedback provide invaluable insights into product performance over time. Platforms where users share their experiences can be gold mines for identifying potential issues and solutions before making any procurement decisions. Installation and maintenance practices also significantly impact the effectiveness of a hydraulic hose drag chain. It’s essential to follow the manufacturer's guidelines for installation to prevent misalignment and slippage of the chain, which can otherwise lead to component fatigue. Regular maintenance checks, including inspection for wear and tear and testing of flexibility, ensure the drag chain remains in peak condition. Moreover, the integration of modern technologies in hydraulic hose drag chains presents exciting innovations. Features such as noise reduction technology, modular links for easy customization, and self-lubricating materials can provide added value to the hydraulic systems. Lastly, environmental considerations must be made when selecting a drag chain. Industrial processes now lean towards sustainable practices. Selecting chains made from recyclable materials not only supports environmental efforts but positions a company as a forward-thinking and responsible entity. In conclusion, the choice of a hydraulic hose drag chain requires a balanced consideration of material science, precise engineering, trusted manufacturing, and informed user feedback. By prioritizing these elements, businesses can enhance operational safety, efficiency, and sustainability, gaining a competitive edge in their respective fields. This informed decision-making process will ultimately establish a hydraulic system that stands the test of time, justifying its investment through reliable and safe performance.