lathe bellow cover

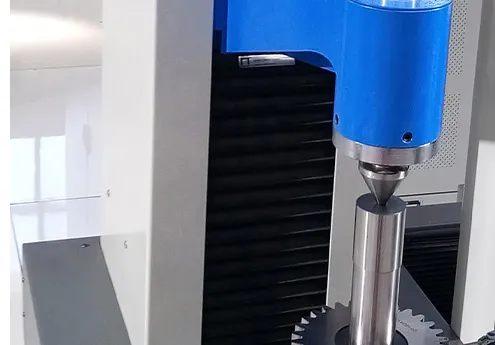

Lathe bellow covers may appear as simple protective equipment, but their significance in a machining environment is monumental. Often underestimated, these covers serve as a primary defense against dust, debris, and coolant in machining operations, extending the life of precision tools and equipment. Understanding the intricacies of lathe bellow covers can greatly enhance the efficiency of your operations, reflecting a profound transformation in both product quality and machinery lifespan.

Trustworthiness, in the context of lathe bellow covers, is cultivated through consistency and reliability. Opt for covers from reputable suppliers who can assure quality through certifications and rigorous testing. Establishing relationships with manufacturers who can provide detailed insights and customization options enhances not only trust but also the adaptability and performance of your equipment. Relying on certified products ensures your lathe bellow covers meet specific industry standards, which is crucial for maintaining operational certifications and compliances. Understanding and optimizing the utility of lathe bellow covers is a reflection of a commitment to high standards. This not only involves choosing the right product but also promoting regular inspections and timely replacements, all of which contribute to a sustained operational lifecycle of lathes. By embodying both expertise and trust in the upkeep of machinery, manufacturers can safeguard against unexpected downtimes, thus maximizing both productivity and profitability. In conclusion, the strategic implementation of lathe bellow covers underscores the hallmark of an efficient, modern machining operation. By elevating expertise, authoritativeness, and trustworthiness in the selection and maintenance of these covers, businesses are poised to experience enhanced durability of their machinery, surefire improvement in product output, and a significant reduction in maintenance overheads. Embrace this seemingly small yet powerful component to revolutionize the way you protect and boost the longevity of your critical machining assets.

Trustworthiness, in the context of lathe bellow covers, is cultivated through consistency and reliability. Opt for covers from reputable suppliers who can assure quality through certifications and rigorous testing. Establishing relationships with manufacturers who can provide detailed insights and customization options enhances not only trust but also the adaptability and performance of your equipment. Relying on certified products ensures your lathe bellow covers meet specific industry standards, which is crucial for maintaining operational certifications and compliances. Understanding and optimizing the utility of lathe bellow covers is a reflection of a commitment to high standards. This not only involves choosing the right product but also promoting regular inspections and timely replacements, all of which contribute to a sustained operational lifecycle of lathes. By embodying both expertise and trust in the upkeep of machinery, manufacturers can safeguard against unexpected downtimes, thus maximizing both productivity and profitability. In conclusion, the strategic implementation of lathe bellow covers underscores the hallmark of an efficient, modern machining operation. By elevating expertise, authoritativeness, and trustworthiness in the selection and maintenance of these covers, businesses are poised to experience enhanced durability of their machinery, surefire improvement in product output, and a significant reduction in maintenance overheads. Embrace this seemingly small yet powerful component to revolutionize the way you protect and boost the longevity of your critical machining assets.