Flexible Bellows Covers for Enhanced Protection and Durability in Machinery Applications

Understanding Machine Bellows Covers An Integral Component in Industrial Applications

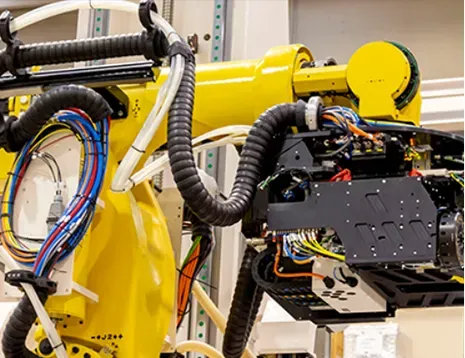

Machine bellows covers are critical components used in various industrial applications to protect machinery and improve operational efficiency. These flexible coverings are designed to shield moving parts from contaminants, such as dust, dirt, and liquids, while also providing a safeguard against physical damage. As industries continue to advance, the role of bellows covers has become increasingly vital in ensuring the longevity and reliability of machinery.

What Are Machine Bellows Covers?

Bellows covers are typically made from durable materials such as rubber, polyurethane, or fabric-reinforced plastics. Their unique design allows them to accommodate movement while maintaining their protective properties. They are commonly used in CNC machines, lathes, milling machines, and robotic arms, where precision and cleanliness are paramount.

The design of bellows covers allows them to expand and contract as machinery operates. This flexibility is critical because it enables the covers to move with the machine parts, preventing any potential entanglement or restriction. Additionally, the accordion-like structure of the bellows provides an effective barrier against harmful elements that could lead to wear and tear of the machinery components.

Types of Bellows Covers

There are several types of machine bellows covers, each suited for specific applications. Some commonly used types include

1. Rectangular Bellows Covers These are often used in linear applications where the movement is primarily in one direction. Their flat, rectangular design allows for optimal coverage along the axes of slideways or other linear components.

2. Cylindrical Bellows Covers Ideal for rotating machinery, cylindrical bellows covers provide protection for shafts and other round components while accommodating rotational movement.

machine bellows covers

3. Custom Bellows Covers Many manufacturers offer custom solutions tailored to unique machinery requirements. This may involve specific dimensions, materials, and shapes to ensure optimal protection and performance.

Benefits of Using Machine Bellows Covers

Implementing machine bellows covers offers numerous advantages

- Protection The primary function of bellows covers is protection. They prevent debris from entering critical areas of machinery, reducing the likelihood of breakdowns and the need for costly repairs.

- Extended Equipment Life By safeguarding machinery components, bellows covers contribute to extending the overall life of industrial equipment. This leads to better return on investment over time.

- Enhanced Safety By covering potentially hazardous moving parts, bellows covers help ensure a safer working environment for operators and maintenance personnel.

- Reduced Maintenance Regular maintenance can be time-consuming and expensive. Machine bellows covers help minimize the amount of maintenance required by keeping machinery clean and in good working order.

Conclusion

In conclusion, machine bellows covers play an essential role in protecting industrial machinery from various environmental factors that can cause damage and wear. Their adaptability, durability, and effectiveness make them an indispensable component in many industries, from manufacturing to robotics. As technology continues to evolve, the design and materials used for bellows covers will likely advance as well, contributing even more significantly to operational efficiency and machinery longevity. Investing in high-quality bellows covers is a smart decision for any business seeking to maintain the integrity and performance of its machines.