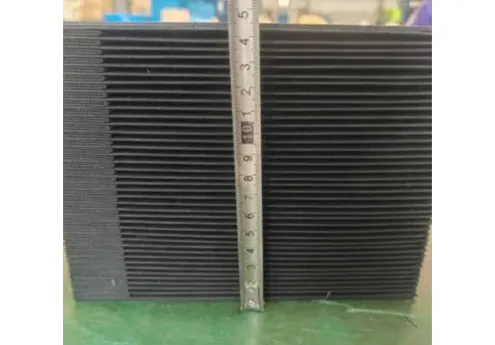

metal chip conveyor

Machine chip conveyors play a crucial role in the manufacturing sector, acting as vital components in ensuring the efficiency and productivity of CNC machining operations. With a focus on enhancing operational workflows, these conveyors streamline the waste management and material handling processes, allowing manufacturing plants to operate smoothly and with reduced downtime.

From a trustworthiness standpoint, companies that produce machine chip conveyors often offer comprehensive customer support and post-sale services. This includes maintenance packages, operational training, and troubleshooting services which build a strong trust with clients, ensuring that their systems remain in top working condition with minimal disruptions. Customer testimonials frequently highlight the reliability and commitment of these companies to uphold the quality and functionality of their products. By investing in state-of-the-art chip conveyors, manufacturers can position themselves as leaders in innovation and operational excellence. The future of manufacturing relies on automation and efficiency, and machine chip conveyors are an essential element in this progression. Their ability to enhance productivity, extend machinery life, and secure compliance with health, safety, and environmental standards underscores their importance across multiple industrial applications. In conclusion, machine chip conveyors embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. They are not merely auxiliary components but essential instruments that drive manufacturing success. As more industries recognize their value, the demand for advanced, reliable chip conveyor systems is set to rise, solidifying their presence as a cornerstone of modern manufacturing.

From a trustworthiness standpoint, companies that produce machine chip conveyors often offer comprehensive customer support and post-sale services. This includes maintenance packages, operational training, and troubleshooting services which build a strong trust with clients, ensuring that their systems remain in top working condition with minimal disruptions. Customer testimonials frequently highlight the reliability and commitment of these companies to uphold the quality and functionality of their products. By investing in state-of-the-art chip conveyors, manufacturers can position themselves as leaders in innovation and operational excellence. The future of manufacturing relies on automation and efficiency, and machine chip conveyors are an essential element in this progression. Their ability to enhance productivity, extend machinery life, and secure compliance with health, safety, and environmental standards underscores their importance across multiple industrial applications. In conclusion, machine chip conveyors embody the principles of Experience, Expertise, Authoritativeness, and Trustworthiness. They are not merely auxiliary components but essential instruments that drive manufacturing success. As more industries recognize their value, the demand for advanced, reliable chip conveyor systems is set to rise, solidifying their presence as a cornerstone of modern manufacturing.