machine chip conveyor

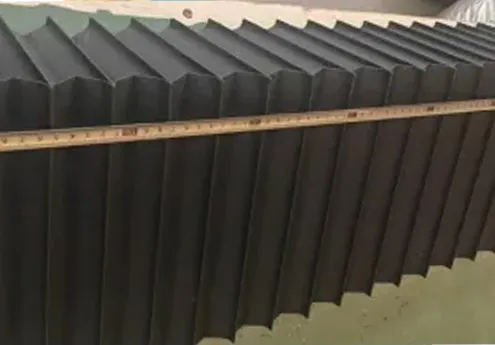

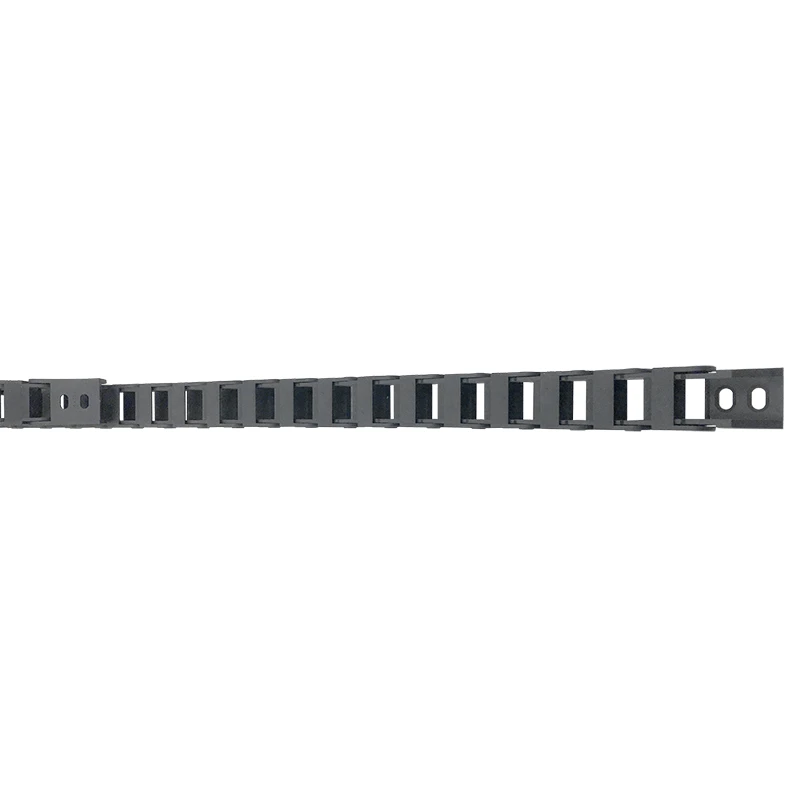

In the modern manufacturing landscape, where precision and efficiency are paramount, machine chip conveyors play a crucial role in ensuring optimal performance and productivity. These innovative systems are designed to handle the challenges faced in manufacturing environments, such as metalworking, where chips and debris can quickly accumulate and disrupt operations. This article delves into the intricacies of machine chip conveyors, offering insights from real-world experiences, highlighting expertise in deployment, and reinforcing the significance of authoritative solutions in the industry.

Moreover, the authoritative nature of machine chip conveyor systems lies in their ability to adapt to environmental and regulatory standards. Modern chip conveyors are built to comply with stringent regulations regarding occupational safety and environmental impact. Their designs often include features like sealed containers to prevent spillages, noise reduction systems, and energy-efficient motors that reduce operational costs while minimizing environmental footprint. In assessing the trustworthiness of machine chip conveyors, one must consider the durability and maintenance requirements of these systems. High-quality conveyors boast robust construction, often utilizing materials resistant to corrosion and wear, ensuring longevity even in demanding conditions. Routine maintenance protocols, supported by reliable customer service and availability of spare parts, further reinforce trust in these systems. Manufacturers of high-value conveyors often provide comprehensive service agreements that cover maintenance, troubleshooting, and training, ensuring uninterrupted operation and immediate resolution of issues. Trust is further built through testimonials and case studies from industry leaders who have successfully integrated machine chip conveyors into their processes. These narratives provide compelling evidence of the positive impact on production efficacy and workflow optimization. One noteworthy example involves a leading automotive parts producer who reported a 20% increase in efficiency after installing a series of customized machine chip conveyors. This case underscores the conveyor's role in facilitating seamless chip management, allowing the company to focus on its core manufacturing processes. In conclusion, the world of machine chip conveyors is defined by a nuanced understanding of manufacturing needs, expert deployment tailored to specific applications, authoritative compliance with industry standards, and unwavering trust in reliability and support. As manufacturers continue to push the boundaries of precision and production, the role of machine chip conveyors will only become more vital, solidifying their position as indispensable tools in the manufacturing industry. Through continuous innovation and adaptation, these systems not only meet present challenges but pave the way for future advancements in industrial efficiency and sustainability.

Moreover, the authoritative nature of machine chip conveyor systems lies in their ability to adapt to environmental and regulatory standards. Modern chip conveyors are built to comply with stringent regulations regarding occupational safety and environmental impact. Their designs often include features like sealed containers to prevent spillages, noise reduction systems, and energy-efficient motors that reduce operational costs while minimizing environmental footprint. In assessing the trustworthiness of machine chip conveyors, one must consider the durability and maintenance requirements of these systems. High-quality conveyors boast robust construction, often utilizing materials resistant to corrosion and wear, ensuring longevity even in demanding conditions. Routine maintenance protocols, supported by reliable customer service and availability of spare parts, further reinforce trust in these systems. Manufacturers of high-value conveyors often provide comprehensive service agreements that cover maintenance, troubleshooting, and training, ensuring uninterrupted operation and immediate resolution of issues. Trust is further built through testimonials and case studies from industry leaders who have successfully integrated machine chip conveyors into their processes. These narratives provide compelling evidence of the positive impact on production efficacy and workflow optimization. One noteworthy example involves a leading automotive parts producer who reported a 20% increase in efficiency after installing a series of customized machine chip conveyors. This case underscores the conveyor's role in facilitating seamless chip management, allowing the company to focus on its core manufacturing processes. In conclusion, the world of machine chip conveyors is defined by a nuanced understanding of manufacturing needs, expert deployment tailored to specific applications, authoritative compliance with industry standards, and unwavering trust in reliability and support. As manufacturers continue to push the boundaries of precision and production, the role of machine chip conveyors will only become more vital, solidifying their position as indispensable tools in the manufacturing industry. Through continuous innovation and adaptation, these systems not only meet present challenges but pave the way for future advancements in industrial efficiency and sustainability.