Leading Manufacturer of Magnetic Chip Conveyors for Efficient Metal Handling Solutions

The Importance of Magnetic Chip Conveyors in Modern Manufacturing

In today’s fast-paced manufacturing environment, efficiency and precision are paramount. One of the key components that contribute to these objectives is the magnetic chip conveyor. These specialized conveyors play a crucial role in the management of metal shavings and chips produced during machining processes. By incorporating advanced magnetic technology, manufacturers can enhance their operations significantly.

Magnetic chip conveyors are designed to transport ferrous materials, primarily metal chips and scrap, directly from machining stations to disposal or recycling areas. The unique feature of these conveyors lies in their ability to utilize magnetic forces to securely hold and move metal chips. This method not only minimizes the risk of spills and contamination but also ensures a clean and efficient production line.

One of the primary advantages of magnetic chip conveyors is their ability to streamline the workflow in a manufacturing plant. Traditional conveyor systems often rely on gravity or mechanical movement, which can sometimes lead to blockages, extensive maintenance, and even safety hazards. In contrast, magnetic conveyors provide a reliable solution by continuously transporting metal waste without the need for additional assistance. This capability reduces downtime and enhances productivity, allowing manufacturers to focus on their core operations.

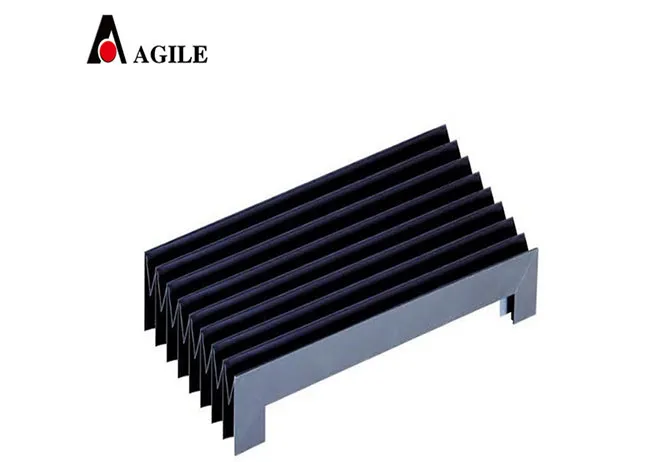

magnetic chip conveyor manufacturer

Moreover, magnetic chip conveyors are highly customizable. Manufacturers can tailor the size, speed, and layout to meet specific operational needs. This flexibility is critical as production requirements can vary based on the type of machinery in use and the kind of materials being processed. By selecting the right specifications, companies can optimize their waste management processes and improve overall efficiency.

Another significant benefit of magnetic chip conveyors is their contribution to sustainability. With an increasing emphasis on environmentally friendly practices, manufacturers are seeking ways to recycle metal scrap effectively. Magnetic chip conveyors facilitate the collection of metal chips, making it easier to recycle ferrous materials. By reducing waste and promoting recycling, manufacturers can significantly lessen their environmental impact while also potentially lowering costs associated with waste disposal.

Safety is another critical consideration in manufacturing environments. Magnetic chip conveyors eliminate the need for workers to manually handle hazardous materials, thus reducing the risk of injury. Additionally, the enclosed design of many magnetic conveyors protects operators from sharp metal edges, further enhancing workplace safety.

In summary, magnetic chip conveyors are an invaluable asset for modern manufacturers. They improve efficiency by streamlining processes, offer customization to meet specific needs, promote sustainability through effective scrap collection, and enhance safety in the workplace. As the manufacturing sector continues to evolve and embrace advanced technologies, the role of magnetic chip conveyors will undoubtedly become even more pivotal in maintaining competitive advantages and operational excellence. Companies looking to enhance their manufacturing capabilities should seriously consider integrating magnetic chip conveyor systems into their production lines for a more efficient, safe, and environmentally-friendly operation.