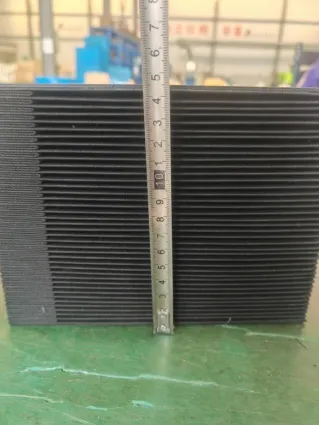

metal chip conveyor

Navigating the realm of industrial operations, metal chip conveyors play a pivotal role in enhancing productivity, safety, and overall efficiency. Metal chip conveyors, integral to manufacturing sectors like automotive, aerospace, and machinery fabrication, effectively manage waste and maintain cleanliness on the production floor. Their ability to transport metal shavings, scraps, and chips from machining processes not only streamlines operations but also safeguards equipment and maintains a safer work environment.

Expertise in selecting and maintaining metal chip conveyors can significantly augment their efficacy. Workers and managers should be versed in the different types of conveyors available, such as hinged belt, drag, magnetic, and screw conveyors, to name a few. Each type serves distinct needs and operational contexts. Hinged belt conveyors, for example, are renowned for handling large volumes of chips, making them ideal for heavy-duty applications. On the other hand, magnetic conveyors are optimal for smaller ferrous chips, as they efficiently use magnetic forces to extract materials. Trustworthiness in the market is an asset for manufacturers and suppliers of metal chip conveyors. Companies that provide comprehensive support services, from installation to after-sales, establish themselves as reliable partners in production efficiency. Regular training sessions for staff on the proper usage and maintenance of these conveyors ensure a sustainable operation, while systematic troubleshooting processes minimize the risk of operational disruptions. Understanding the authority that a trusted supplier or manufacturer of metal chip conveyors carries is crucial for businesses looking to implement these systems. Established manufacturers typically have decades of experience and innovation behind their products, providing a wealth of knowledge that the buyers can capitalize on. This experience translates into conveyors that not only meet but exceed industry standards in performance and safety, further bolstering a facility’s compliance credentials. In conclusion, the incorporation of metal chip conveyors within the manufacturing process is a strategic enhancement to operational efficiency and sustainability. Their role in waste management and environmental conservation is indispensable, aligning operational processes with modern-day ecological imperatives. Furthermore, leveraging the expertise and trustworthy standing of seasoned manufacturers ensures that a facility runs optimally, with minimal interruptions and maximal efficiency. Investing in these conveyors is not merely a matter of immediate need but a long-term commitment to excellence and sustainable growth within the industry.

Expertise in selecting and maintaining metal chip conveyors can significantly augment their efficacy. Workers and managers should be versed in the different types of conveyors available, such as hinged belt, drag, magnetic, and screw conveyors, to name a few. Each type serves distinct needs and operational contexts. Hinged belt conveyors, for example, are renowned for handling large volumes of chips, making them ideal for heavy-duty applications. On the other hand, magnetic conveyors are optimal for smaller ferrous chips, as they efficiently use magnetic forces to extract materials. Trustworthiness in the market is an asset for manufacturers and suppliers of metal chip conveyors. Companies that provide comprehensive support services, from installation to after-sales, establish themselves as reliable partners in production efficiency. Regular training sessions for staff on the proper usage and maintenance of these conveyors ensure a sustainable operation, while systematic troubleshooting processes minimize the risk of operational disruptions. Understanding the authority that a trusted supplier or manufacturer of metal chip conveyors carries is crucial for businesses looking to implement these systems. Established manufacturers typically have decades of experience and innovation behind their products, providing a wealth of knowledge that the buyers can capitalize on. This experience translates into conveyors that not only meet but exceed industry standards in performance and safety, further bolstering a facility’s compliance credentials. In conclusion, the incorporation of metal chip conveyors within the manufacturing process is a strategic enhancement to operational efficiency and sustainability. Their role in waste management and environmental conservation is indispensable, aligning operational processes with modern-day ecological imperatives. Furthermore, leveraging the expertise and trustworthy standing of seasoned manufacturers ensures that a facility runs optimally, with minimal interruptions and maximal efficiency. Investing in these conveyors is not merely a matter of immediate need but a long-term commitment to excellence and sustainable growth within the industry.