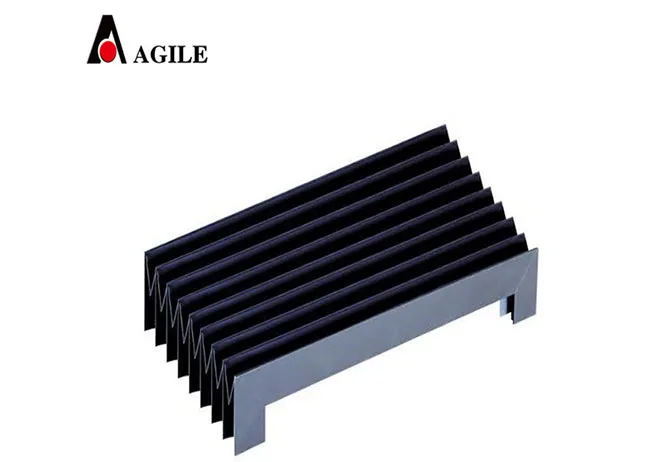

small cable track

Moving cable tracks, often interchangeable with energy chains or drag chains, have become indispensable components in modern automated systems. Their pivotal role transcends mere mechanical support—they serve as lifelines for data and energy transfer, ensuring seamless operation within dynamic environments. Drawing from decades of engineering innovations, this guide delves into the intricacies of moving cable tracks, poised as a beacon of reliability and efficiency.

Trustworthiness, a cornerstone in this realm, is fortified by transparency and customer feedback. Leading manufacturers offer extensive warranties and lifetime service promises, instilling confidence in their innovations. Furthermore, user testimonials from various sectors—ranging from logistics to pharmaceuticals—substantiate claims of reduced maintenance costs and enhanced operational capabilities facilitated by these cable tracks. Evolving beyond traditional roles, moving cable tracks embrace the digital age with smart capabilities. Cutting-edge models equipped with sensors now monitor and transmit real-time data about tension and wear, predictive analytics foreseeing and forestalling malfunctions before they disrupt processes. This attribute not only extends the service life of the equipment but also optimizes planning and resource allocation, epitomizing proactive maintenance strategies. The future trajectory of moving cable tracks is set towards greater integration with IoT ecosystems, further amplifying automated functionalities. As smart factories burgeon, the demand for adaptable, intelligent solutions will rise, prompting continual enhancements. By staying abreast of technological advances, stakeholders can harness these developments, aligning their operational strategies with transformative tools that drive productivity and sustainability. In conclusion, moving cable tracks, though often concealed behind the scenes, are linchpins of modern automation. They embody a synthesis of expertise, experience, authoritativeness, and trustworthiness—a blend that propels industries forward. As they occupy an increasingly strategic role in technology ecosystems, their evolution will undeniably parallel the rapid pace of industrial advancement, underscoring their indispensable value in the orchestration of future-centric manufacturing landscapes.

Trustworthiness, a cornerstone in this realm, is fortified by transparency and customer feedback. Leading manufacturers offer extensive warranties and lifetime service promises, instilling confidence in their innovations. Furthermore, user testimonials from various sectors—ranging from logistics to pharmaceuticals—substantiate claims of reduced maintenance costs and enhanced operational capabilities facilitated by these cable tracks. Evolving beyond traditional roles, moving cable tracks embrace the digital age with smart capabilities. Cutting-edge models equipped with sensors now monitor and transmit real-time data about tension and wear, predictive analytics foreseeing and forestalling malfunctions before they disrupt processes. This attribute not only extends the service life of the equipment but also optimizes planning and resource allocation, epitomizing proactive maintenance strategies. The future trajectory of moving cable tracks is set towards greater integration with IoT ecosystems, further amplifying automated functionalities. As smart factories burgeon, the demand for adaptable, intelligent solutions will rise, prompting continual enhancements. By staying abreast of technological advances, stakeholders can harness these developments, aligning their operational strategies with transformative tools that drive productivity and sustainability. In conclusion, moving cable tracks, though often concealed behind the scenes, are linchpins of modern automation. They embody a synthesis of expertise, experience, authoritativeness, and trustworthiness—a blend that propels industries forward. As they occupy an increasingly strategic role in technology ecosystems, their evolution will undeniably parallel the rapid pace of industrial advancement, underscoring their indispensable value in the orchestration of future-centric manufacturing landscapes.