non split loom

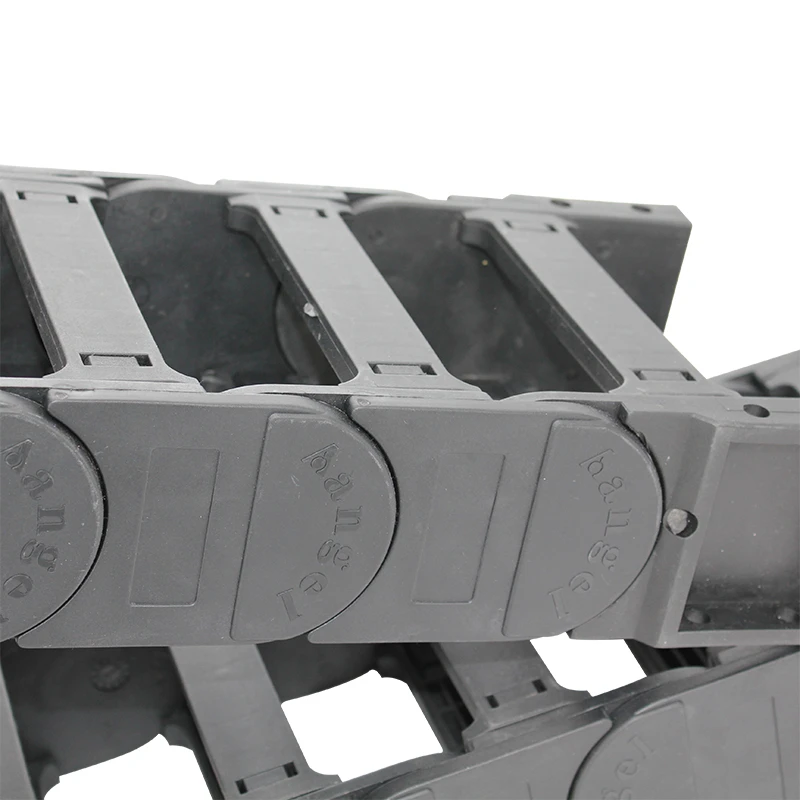

Understanding the intricacies of non-split loom tubing is essential for anyone interested in cable management and protection. Widely used in the automotive, marine, and electronic industries, non-split loom offers a range of benefits that cater to both professional and DIY applications.

Professionals also appreciate the versatility of non-split loom tubing. Available in a variety of diameters and materials, it can be tailored to suit specific needs. For automotive applications, heat-resistant options are available, ensuring that wiring is protected from high engine temperatures. For applications requiring extra strength, metal-reinforced looms provide an added layer of defense against external pressures. Environmentally conscious users will also be pleased to learn that many manufacturers now offer eco-friendly non-split loom options. These are made from recyclable materials without compromising on performance. This not only benefits the environment but often results in cost savings over time, as the longevity of the product reduces the frequency of replacements. When it comes to navigating the vast marketplace for non-split loom, selecting a reputable brand is crucial. Top manufacturers will provide products that meet industry standards, ensuring reliability and safety. It’s also beneficial to consider brands with strong customer service and comprehensive warranties. These factors build trust, reassuring you that support is available should any issues arise. In transforming cable management through the use of non-split loom tubing, both amateurs and experts can achieve high levels of efficiency and safety. By choosing the right specifications and materials, users can tailor their selection to meet specific project requirements. The combination of robustness, flexibility, and security positions non-split loom as a leader in the cable protection industry. Finally, reviews and testimonials provide an invaluable resource for assessing the performance of non-split loom products. Learning from the experiences of both seasoned professionals and novice users helps guide purchasing decisions and optimizes application strategies. Trusting in well-documented success stories reinforces the decision to incorporate non-split loom into any project, ensuring that cables remain protected and systems run smoothly.

Professionals also appreciate the versatility of non-split loom tubing. Available in a variety of diameters and materials, it can be tailored to suit specific needs. For automotive applications, heat-resistant options are available, ensuring that wiring is protected from high engine temperatures. For applications requiring extra strength, metal-reinforced looms provide an added layer of defense against external pressures. Environmentally conscious users will also be pleased to learn that many manufacturers now offer eco-friendly non-split loom options. These are made from recyclable materials without compromising on performance. This not only benefits the environment but often results in cost savings over time, as the longevity of the product reduces the frequency of replacements. When it comes to navigating the vast marketplace for non-split loom, selecting a reputable brand is crucial. Top manufacturers will provide products that meet industry standards, ensuring reliability and safety. It’s also beneficial to consider brands with strong customer service and comprehensive warranties. These factors build trust, reassuring you that support is available should any issues arise. In transforming cable management through the use of non-split loom tubing, both amateurs and experts can achieve high levels of efficiency and safety. By choosing the right specifications and materials, users can tailor their selection to meet specific project requirements. The combination of robustness, flexibility, and security positions non-split loom as a leader in the cable protection industry. Finally, reviews and testimonials provide an invaluable resource for assessing the performance of non-split loom products. Learning from the experiences of both seasoned professionals and novice users helps guide purchasing decisions and optimizes application strategies. Trusting in well-documented success stories reinforces the decision to incorporate non-split loom into any project, ensuring that cables remain protected and systems run smoothly.