Nylon Conduit - Durable and Flexible Cable Protection Solutions

Understanding Nylon Conduit Applications and Benefits

Nylon conduit has emerged as a popular choice in various industries due to its versatility, durability, and unique properties. This type of conduit is primarily used for protecting electrical wires and cables, offering numerous advantages over traditional materials like metal or PVC. In this article, we will delve into the features, applications, and benefits of nylon conduit, highlighting its growing significance in modern construction and electrical installations.

What is Nylon Conduit?

Nylon conduit is constructed from high-quality nylon, a synthetic polymer known for its strength, flexibility, and resistance to various chemicals. Unlike traditional conduits made from materials like metal or PVC, nylon provides an excellent protective sleeve for electrical wiring, ensuring safety and longevity in installations. Its lightweight nature combined with its sturdy construction makes it an ideal choice for many applications.

Advantages of Nylon Conduit

1. Durability One of the standout features of nylon conduit is its remarkable durability. It can withstand harsh environmental conditions, including extreme temperatures, ultraviolet (UV) exposure, and moisture. This makes it suitable for both indoor and outdoor applications, ensuring that electrical systems remain safe and functional over time.

2. Chemical Resistance Nylon conduit is highly resistant to many chemicals, including oils, solvents, and acids. This property makes it an excellent choice for industries that involve exposure to harsh chemicals, such as manufacturing, automotive, and petrochemical sectors.

3. Flexibility The inherent flexibility of nylon allows for easier installation, especially in tight or irregular spaces. Electricians and technicians favor nylon conduit as it can be bent and shaped without compromising its structural integrity, facilitating the routing of cables through complicated pathways.

4. Lightweight Compared to metal conduits, nylon is significantly lighter, which reduces transportation costs and makes installation easier. The lightweight nature does not compromise strength, providing a robust solution for wire protection.

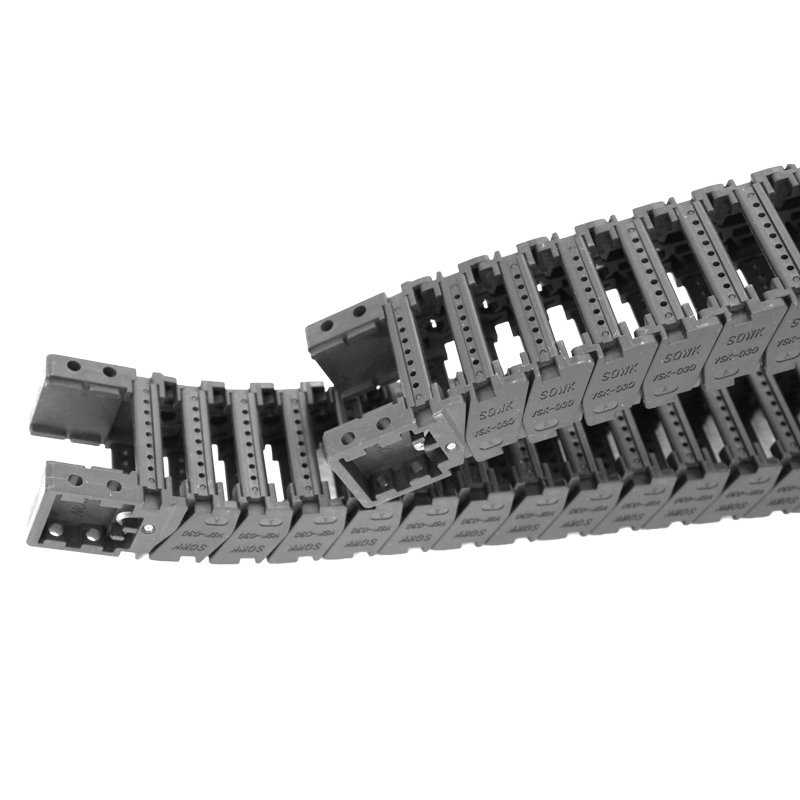

nylon conduit

5. Cost-Effective While the initial investment for nylon conduit may be higher than PVC, its durability and lower maintenance requirements can lead to cost savings over the lifespan of the installation. This makes it a smart choice for long-term projects.

Applications of Nylon Conduit

Nylon conduit is utilized in various applications across multiple industries

- Construction In both residential and commercial buildings, nylon conduit is used for wiring protection, ensuring that electrical systems remain safe from environmental hazards. - Automotive The automotive industry employs nylon conduit for harnessing and protecting electrical wiring in vehicles, particularly in harsh operating conditions.

- Industrial Manufacturing facilities utilize nylon conduit for machinery and equipment wiring, where exposure to chemicals and extreme conditions is common.

- Telecommunications The telecommunications sector uses nylon conduit to protect and manage fiber optic and other communication cables, ensuring reliable connectivity.

Conclusion

In summary, nylon conduit represents a modern solution to traditional wire protection needs. Its durability, chemical resistance, flexibility, and lightweight nature make it an ideal choice for a wide range of applications in various industries. As more industries recognize the advantages of nylon conduit, its adoption continues to grow, paving the way for safer and more efficient electrical installations. Whether in construction, automotive, industrial, or telecommunications, nylon conduit is proving to be an indispensable component in modern infrastructure.