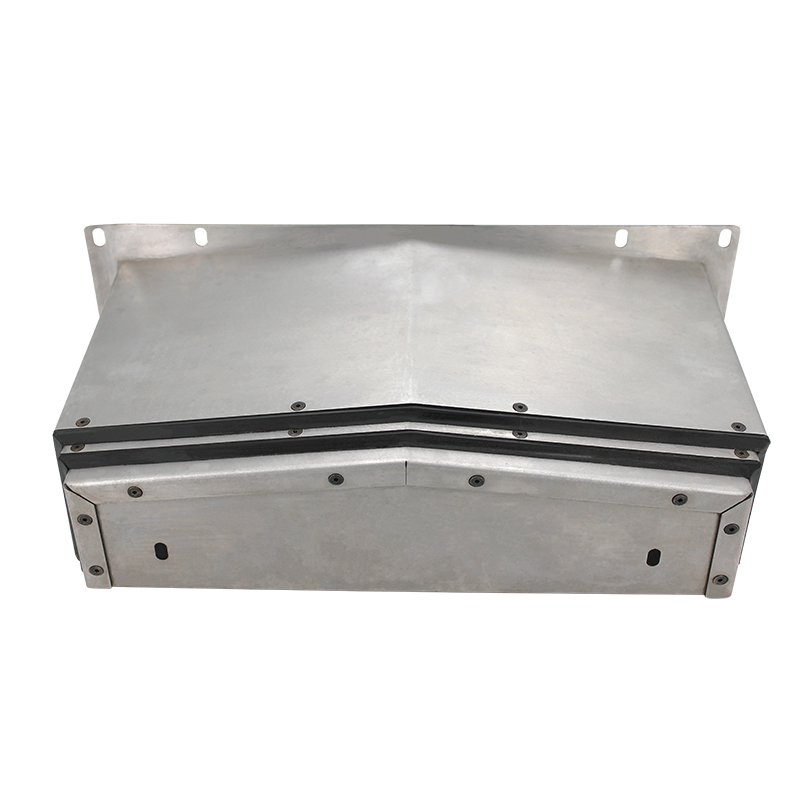

nylon cable chain

The Versatility and Importance of Nylon Cable Chains

Nylon cable chains, also known as cable drag chains or cable carriers, play a critical role in various industries by facilitating the safe and efficient management of cables and hoses. These innovative solutions are designed to protect and guide cables, wires, and hoses in dynamic environments where movement and flexibility are essential. Their versatility and advantages make them an integral part of modern machinery, robotics, and automation systems.

What are Nylon Cable Chains?

Nylon cable chains are flexible, articulated structures made from high-performance nylon, enabling them to bend and flex without constraints. This flexibility allows them to adapt to the specific movements of machinery, reducing wear and tear on cables while ensuring that they remain organized and protected. The chains consist of individual links that can be connected to form a continuous chain, which effectively guides cables and hoses as they move within machinery.

Advantages of Nylon Cable Chains

1. Durability and Strength Nylon is known for its excellent tensile strength and durability, which make it suitable for harsh environments. Nylon cable chains can withstand significant mechanical stress without breaking or deforming. Additionally, they are resistant to abrasion, chemicals, and temperature fluctuations, further extending their lifespan.

2. Lightweight Design Compared to metal alternatives, nylon cable chains are lightweight, which helps reduce the overall weight of machinery. This is particularly beneficial in applications where minimizing weight is crucial for performance and efficiency.

nylon cable chain

3. Noise Reduction The use of nylon can significantly reduce noise levels produced by moving cables and hoses. This characteristic is essential in environments where noise pollution needs to be minimized, such as hospitals and offices.

4. Flexibility Nylon cable chains can be designed with varying bend radii to accommodate different movement patterns of machinery. This adaptability means they can be used in various settings, from CNC machines to robotic arms, seamlessly integrating into diverse operational requirements.

5. Ease of Installation and Maintenance Installing nylon cable chains is generally straightforward, allowing for quick assembly and disassembly during maintenance. This ease of access ensures that repairs or replacements can be performed swiftly, minimizing downtime in production environments.

Applications of Nylon Cable Chains

The applications of nylon cable chains are vast and varied. They are widely utilized in manufacturing processes, automotive assembly lines, and automated guided vehicles (AGVs). Robotics, especially, has seen significant integration of nylon cable chains due to the precise and dynamic movements required. Additionally, they are beneficial in industries like electronics, textile manufacturing, and aerospace, where organized and protected cabling is essential.

Conclusion

In summary, nylon cable chains are an indispensable component in the modern industrial landscape. Their combination of strength, flexibility, and durability makes them an ideal choice for managing cables and hoses in a variety of applications. As industries continue to evolve and automate, the role of nylon cable chains will likely expand, ensuring that our machinery remains efficient, organized, and operational. Investing in high-quality nylon cable chains is not just a decision for today; it is a commitment to the future of efficient industrial processes.