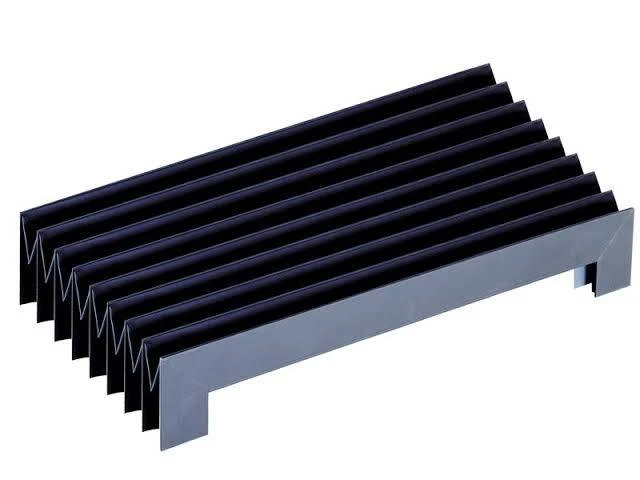

plastic cable carrier chain

Understanding Plastic Cable Carrier Chains Essential Components for Modern Machinery

In the realm of industrial automation and machinery engineering, plastic cable carrier chains have emerged as an indispensable component. Known for their versatility, durability, and lightweight properties, these chains play a critical role in managing and protecting cables and hoses in motion applications. Whether in CNC machines, robotics, or conveyor systems, plastic cable carrier chains provide an effective solution to numerous challenges posed by traditional cable management methods.

What Are Plastic Cable Carrier Chains?

Plastic cable carrier chains, often referred to as energy chains, are specially designed conduits for guiding and protecting flexible cables and hydraulic hoses. Made from high-quality plastics such as nylon, polyurethane, or acetal, these chains are engineered to withstand rigorous movements and environmental conditions. They are typically comprised of a series of interconnected links that allow the chains to flex and bend without kinking or damaging the cables inside.

Advantages of Plastic Cable Carrier Chains

One of the most significant advantages of plastic cable carrier chains is their lightweight nature. Compared to metal alternatives, plastic chains reduce the overall weight of the machinery, leading to lower energy consumption and enhancing efficiency. This weight reduction becomes particularly beneficial in applications involving high-speed motion, as it minimizes inertia and allows for quicker acceleration and deceleration.

In addition, plastic chains are often more resistant to corrosion, chemicals, and UV exposure compared to metal chains. This makes them ideal for use in various environments, including those that are wet, harsh, or exposed to temperature fluctuations. Furthermore, the noise-dampening properties of plastic contribute to a quieter operation, improving the working conditions in industrial settings.

plastic cable carrier chain

Applications of Plastic Cable Carrier Chains

Plastic cable carrier chains are employed in a wide array of applications across different industries. In the manufacturing sector, they are integral to automated machinery where cables must move with the equipment's movements. They are commonly used in CNC machines, laser cutting systems, and robotic arms. By providing a reliable method of cable management, they help to prevent wear and tear, reducing maintenance costs and downtime.

In addition, plastic cable carrier chains are frequently found in the transportation industry, particularly in conveyor systems that handle goods and materials. These systems rely on robust cable management to ensure smooth operation over extended periods while minimizing the risk of cable damage.

Installation and Maintenance

Installing plastic cable carrier chains is a straightforward process that can often be completed without specialized tools. The ability to easily open and close the chain links allows for quick cable installation and replacement, which is a significant advantage in fast-paced manufacturing environments. Regular maintenance involves inspecting the chains for wear, ensuring that they are clean and free from debris, and checking the cables for any signs of damage.

Conclusion

In summary, plastic cable carrier chains are a vital component in modern machinery and automation processes. Their lightweight, durable design, coupled with resistance to various environmental factors, makes them an ideal choice for a multitude of applications. As industries continue to evolve and become more reliant on automated systems, the significance of effective cable management solutions like plastic cable carrier chains will undoubtedly grow. Investing in these components not only enhances operational efficiency but also contributes to increased safety and longevity of equipment, paving the way for innovations in machinery design and engineering.