Exploring the Benefits and Applications of Plastic Cable Chains in Modern Industries

Exploring the Versatility of Plastic Cable Chains

In the modern world where technology and industry are continually evolving, the role of components that facilitate movement and organization is crucial. Among these components, plastic cable chains have emerged as a vital solution for managing and protecting cables and hoses in a variety of applications. These conduits not only streamline operations but also enhance safety and efficiency across various industries.

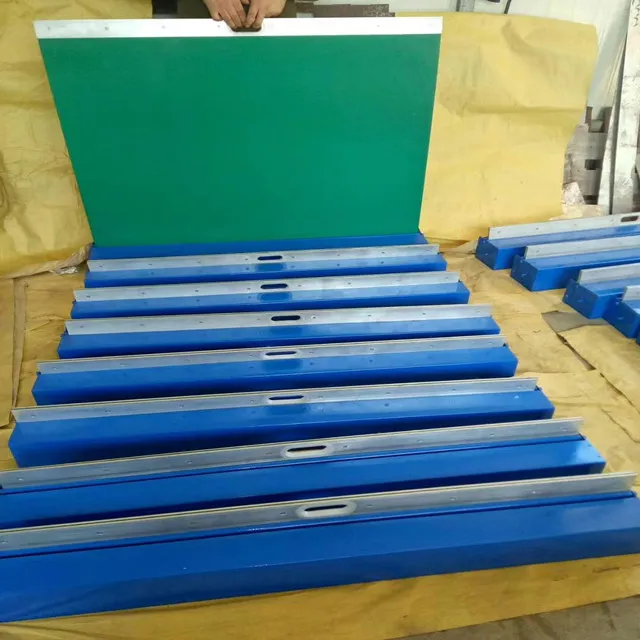

Plastic cable chains, also known as drag chains or energy chains, are designed to guide and protect moving cables and hoses within machinery and equipment. Their robust nature makes them ideal for dynamic applications where repetitive motion and limited flexibility are common. The design of these chains allows for easy installation and provides a simplified method for organizing cables, ultimately minimizing wear and tear caused by friction and movement.

One of the most significant advantages of plastic cable chains is their lightweight composition. Unlike metal counterparts, which can be heavy and cumbersome, plastic chains provide the necessary strength while significantly reducing overall weight. This characteristic is particularly beneficial in industries such as automation, robotics, and aerospace, where weight reduction can lead to improved performance and energy efficiency. The flexibility of plastic also allows for various designs and configurations, making them adaptable to diverse environments and machinery.

Moreover, plastic cable chains are resistant to various harsh environmental factors, including chemicals, oils, and extreme temperatures

. This durability ensures that they can be utilized in demanding sectors such as manufacturing, automotive, and even marine applications, where exposure to corrosive substances is commonplace. Furthermore, the material used in plastic chains can be tailored to meet specific environmental conditions, extending their lifespan and reliability.plastic cable chain

Another critical consideration in the use of plastic cable chains is their impact on safety. By keeping cables and hoses organized and protected, these chains help prevent accidents related to tripping hazards or equipment malfunctions. In an industrial setting where machinery operates continuously, the risk of loose or frayed cables can lead to operational downtime and increased maintenance costs. Plastic cable chains significantly mitigate these risks by providing a secure pathway for cable movement.

In addition to safety and durability, the versatility of plastic cable chains allows them to be used in various applications. From CNC machines and conveyor systems to robotic arms and medical devices, their presence is ubiquitous in the modern industrial landscape. This adaptability also allows engineers to design more efficient systems, as cable chains can be incorporated into existing frameworks without significant modifications.

Sustainability is another crucial aspect of the growing interest in plastic cable chains. Many manufacturers are now producing these components using recyclable materials, promoting eco-friendly practices within the industry. As companies strive to reduce their carbon footprint, adopting solutions like plastic cable chains can contribute to larger sustainability goals.

In conclusion, plastic cable chains are becoming an indispensable part of modern machinery and equipment design. Their lightweight, durable, and flexible nature makes them ideal for various applications across numerous industries. By enhancing safety, reducing maintenance costs, and promoting sustainable practices, plastic cable chains stand at the forefront of industrial advancements. As technology continues to progress, it is likely that the importance and sophistication of these components will only grow, further solidifying their place in the modern industrial toolbox.