plastic cable chain track

Understanding Plastic Cable Chain Tracks Benefits and Applications

In the modern manufacturing landscape, ensuring the safe and efficient movement of cables and hoses is a critical aspect of operational productivity. One of the prominent solutions employed for this purpose is the plastic cable chain track, also known as a drag chain or energy chain. These specialized systems play a vital role in managing the complex arrangements of cables and hoses found in automated machinery, robotics, and various industrial applications.

What is a Plastic Cable Chain Track?

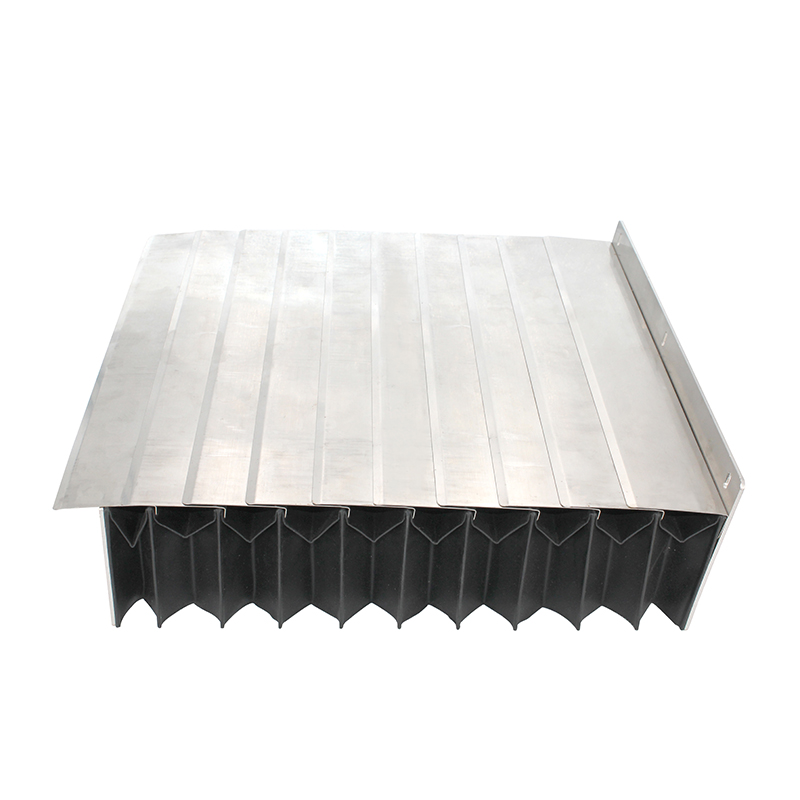

A plastic cable chain track is a flexible system designed to guide and protect cables and hoses as they move in tandem with machinery. Composed primarily of high-strength plastic materials, these tracks can be engineered to accommodate various sizes and types of cables, ensuring they remain organized, undamaged, and free from excessive wear during operation. The design typically features interconnected links that allow the chain to flex and bend as required, making it ideal for environments where movement is frequent and dynamic.

Key Benefits

1. Durability and Longevity Plastic cable chain tracks are designed to withstand the rigors of industrial environments. They resist wear and tear from repeated movement and can endure extreme temperatures and chemical exposure without degrading. This durability translates to a longer service life compared to traditional metal tracks.

2. Reduced Maintenance Integrating a plastic cable chain track into your machinery setup can significantly lower maintenance costs. The design minimizes cable tangling and kinking, reducing the likelihood of cable failure and the need for frequent replacements. This efficiency leads to reduced downtime and more consistent production schedules.

3. Versatile Design One of the remarkable features of plastic cable chain tracks is their versatility. They are available in a variety of shapes, sizes, and configurations, allowing them to be customized for a wide range of applications—from simple machinery to complex robotic arms. This adaptability makes them suitable for industries ranging from automotive manufacturing to electronics assembly.

4. Noise Reduction The plastic material of the chain reduces the noise generated during operation compared to metal chains. This quieter operation is particularly beneficial in environments where sound pollution can be a concern, contributing to a more pleasant working atmosphere.

plastic cable chain track

5. Easy Installation Plastic cable chain tracks are easier to install than their metal counterparts. Their lightweight nature, along with user-friendly connectors and assembly systems, allows for quick setup and integration into existing machinery.

Applications of Plastic Cable Chain Tracks

The applications of plastic cable chain tracks are vast and varied. Here are some of the most common industries that utilize them

- Automation and Robotics In automated systems, including robots and conveyor belts, cable chain tracks are essential for keeping power and control cables organized. They enable smooth movement and prevent cable damage during cyclical operations.

- CNC Machines Computer Numerical Control (CNC) machines often require the precise management of multiple cables. Plastic cable chain tracks help maintain order and ensure that cables are kept away from moving parts while providing flexibility for machine operations.

- 3D Printing In 3D printers, managing the numerous cables involved in printing activities is crucial. Cable chain tracks facilitate movement without affecting the quality of prints, ensuring that materials and power supply lines remain intact.

- Material Handling Systems In warehouses and distribution centers, equipment such as automated guided vehicles (AGVs) benefit greatly from the efficient management of power and signaling cables, where cable chain tracks play a pivotal role.

Conclusion

Plastic cable chain tracks are an invaluable component in various industrial applications. With their robust design, noise-reducing qualities, and ease of installation, they significantly enhance operational efficiency and reliability. As the manufacturing landscape continues to evolve, the role of these cable management solutions will likely expand, improving workflow and increasing productivity across numerous sectors. Embracing this technology can lead to smarter, more organized, and ultimately more profitable operations. By investing in plastic cable chain tracks, businesses can ensure that their machinery runs smoothly and effectively, paving the way for innovation and growth in an increasingly competitive market.