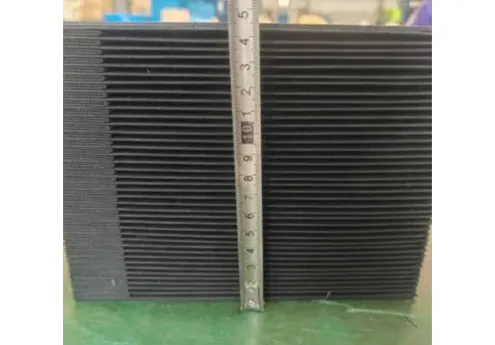

small cable track

Plastic cable tracks have emerged as a crucial component in modern industries, facilitating the seamless management and protection of cables and hoses that power complex machinery. These robust devices ensure operational efficiency and safety across various sectors, including automation, robotics, and manufacturing.

In the realm of automation and robotics, where precision and reliability are non-negotiable, plastic cable tracks play a vital role. They help maintain systematic organization and separation of cables, preventing tangling and abrasion that can lead to costly downtimes. Moreover, their smooth interior surfaces reduce friction, ensuring that cables slide effortlessly within the track, which is crucial for maintaining the optimum performance of robotic arms and intricate machinery. The credibility of plastic cable tracks is further underscored by rigorous testing protocols ensuring their compliance with international safety and quality standards. Manufacturers continuously innovate to meet the evolving demands of modern technology, integrating smart features such as wear indicators and advanced locking mechanisms. This commitment to quality and innovation reinforces trust and reliance on plastic cable tracks as a foundational element in optimized industrial setups. Adopting plastic cable tracks ultimately means investing in a system designed for durability, performance, and adaptability. Their use reflects a forward-thinking approach to industrial design, where maintenance savings, operational efficiency, and enhanced safety converge to deliver a competitive advantage. Selecting and implementing these devices is best guided by experts who understand the nuances of cable management solutions, ensuring that each application is tailored to meet specific operational demands. In conclusion, plastic cable tracks stand out as a cost-effective and reliable solution for managing cable and hose systems across multiple industries. They combine the excellent attributes of flexibility, durability, and adaptability, enabling companies to maintain peak operational standards while safeguarding essential equipment. These characteristics make them indispensable in the quest for optimizing production processes and minimizing the risks associated with cable wear and damage.

In the realm of automation and robotics, where precision and reliability are non-negotiable, plastic cable tracks play a vital role. They help maintain systematic organization and separation of cables, preventing tangling and abrasion that can lead to costly downtimes. Moreover, their smooth interior surfaces reduce friction, ensuring that cables slide effortlessly within the track, which is crucial for maintaining the optimum performance of robotic arms and intricate machinery. The credibility of plastic cable tracks is further underscored by rigorous testing protocols ensuring their compliance with international safety and quality standards. Manufacturers continuously innovate to meet the evolving demands of modern technology, integrating smart features such as wear indicators and advanced locking mechanisms. This commitment to quality and innovation reinforces trust and reliance on plastic cable tracks as a foundational element in optimized industrial setups. Adopting plastic cable tracks ultimately means investing in a system designed for durability, performance, and adaptability. Their use reflects a forward-thinking approach to industrial design, where maintenance savings, operational efficiency, and enhanced safety converge to deliver a competitive advantage. Selecting and implementing these devices is best guided by experts who understand the nuances of cable management solutions, ensuring that each application is tailored to meet specific operational demands. In conclusion, plastic cable tracks stand out as a cost-effective and reliable solution for managing cable and hose systems across multiple industries. They combine the excellent attributes of flexibility, durability, and adaptability, enabling companies to maintain peak operational standards while safeguarding essential equipment. These characteristics make them indispensable in the quest for optimizing production processes and minimizing the risks associated with cable wear and damage.