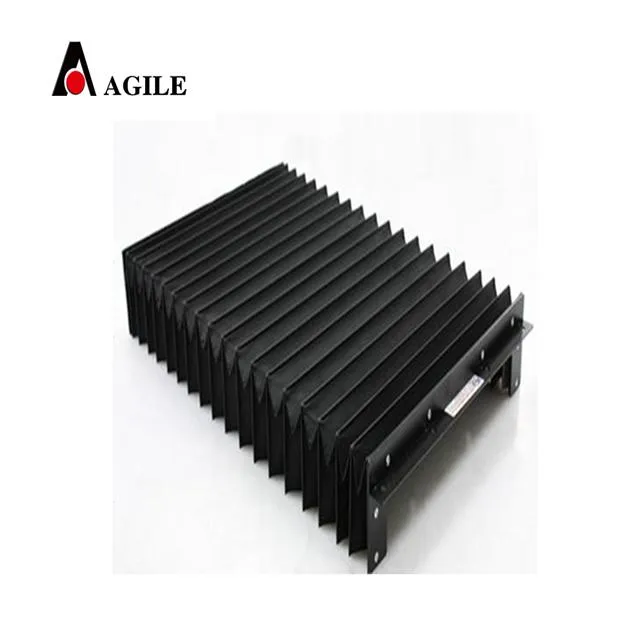

nylon flexible wire loom corrugated bellow conduit hose pipe

Plastic corrugated conduits have become indispensable in various industries due to their versatility and functionality. As a material that combines flexibility, strength, and ease of installation, they offer a solution that suits a wide range of applications. From protecting electrical cabling in construction to serving as a critical component in automotive systems, these conduits ensure safety and durability, making them a top choice among engineers and builders.

From a sustainability perspective, many manufacturers are stepping up by offering conduits made from recycled materials. This shift not only helps in reducing the carbon footprint but also addresses the increasing demand for eco-friendly products. As industries pivot towards more sustainable practices, selecting materials that support these changes becomes a strategic choice. Technological advancements have further enhanced the capabilities of plastic corrugated conduits. New designs and materials have increased their thermal resistance, allowing them to perform effectively in extreme temperatures. Additionally, innovations in manufacturing processes are enabling even more precise dimensions and customizable options, making it possible for businesses to procure conduits that perfectly meet their specific needs. For architects and engineers planning future projects, the integration of plastic corrugated conduits is a forward-thinking choice that ensures adaptability and preparedness for evolving technological standards. Their ability to accommodate future upgrades without needing an entire overhaul of the existing system makes them a favored choice for projects aiming for longevity and flexibility. In conclusion, the role of plastic corrugated conduits in modern infrastructure is vital and ever-growing. Their multifunctional nature, combined with ease of use, durability, and safety, make them a critical component in ensuring the reliability and efficiency of electrical systems across an array of industries. By prioritizing expertise, experience, authoritativeness, and trustworthiness in your projects, selecting plastic corrugated conduits is a decision that underscores a commitment to quality and future-proofing your investments.

From a sustainability perspective, many manufacturers are stepping up by offering conduits made from recycled materials. This shift not only helps in reducing the carbon footprint but also addresses the increasing demand for eco-friendly products. As industries pivot towards more sustainable practices, selecting materials that support these changes becomes a strategic choice. Technological advancements have further enhanced the capabilities of plastic corrugated conduits. New designs and materials have increased their thermal resistance, allowing them to perform effectively in extreme temperatures. Additionally, innovations in manufacturing processes are enabling even more precise dimensions and customizable options, making it possible for businesses to procure conduits that perfectly meet their specific needs. For architects and engineers planning future projects, the integration of plastic corrugated conduits is a forward-thinking choice that ensures adaptability and preparedness for evolving technological standards. Their ability to accommodate future upgrades without needing an entire overhaul of the existing system makes them a favored choice for projects aiming for longevity and flexibility. In conclusion, the role of plastic corrugated conduits in modern infrastructure is vital and ever-growing. Their multifunctional nature, combined with ease of use, durability, and safety, make them a critical component in ensuring the reliability and efficiency of electrical systems across an array of industries. By prioritizing expertise, experience, authoritativeness, and trustworthiness in your projects, selecting plastic corrugated conduits is a decision that underscores a commitment to quality and future-proofing your investments.