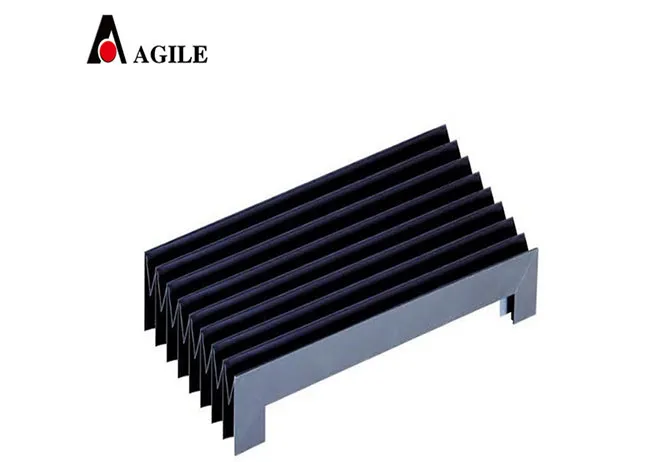

plastic drag chain cable carrier

Understanding Plastic Drag Chain Cable Carriers

In the realm of industrial automation and machinery, the efficient management of cables and hoses is crucial for ensuring smooth operations and minimizing wear and tear. One of the most effective solutions for this is the plastic drag chain cable carrier, a component designed to protect and guide cables and hoses in dynamic applications.

Plastic drag chains, often referred to as cable carriers, are flexible structures that provide a pathway for cables and hoses to move within. They are typically composed of lightweight, durable plastic materials, which makes them ideal for a range of applications, from CNC machines and robotic arms to automotive assembly lines. The design of these carriers allows for both bending and twisting movements, accommodating the dynamic motion commonly experienced in automated systems.

The primary function of a plastic drag chain is to prevent tangling, kinking, and abrasion of cables and hoses during operation. This is particularly important in environments where machinery performs repetitive movements, as harsh conditions can lead to premature wear and potential operational failures. By enclosing cables within a drag chain, the chances of friction against metal surfaces or sharp edges are significantly reduced.

plastic drag chain cable carrier

Furthermore, plastic drag chains are designed with a modular approach, allowing for easy customization and assembly. They come in various sizes, link styles, and configurations to meet specific application requirements. Users can select appropriate chain lengths and widths to suit their machinery's design, making them a highly adaptable solution for diverse operational needs.

Another advantage of plastic drag chain cable carriers is their lightweight nature. This reduces the overall weight of moving components in machinery, contributing to energy efficiency and lower operational costs. Additionally, the smooth inner surfaces of these carriers minimize noise and vibration, enhancing the working environment for operators.

The maintenance of plastic drag chains is relatively straightforward. Regular inspections and occasional cleaning of the chains can prolong their lifespan and ensure optimal performance. Moreover, many manufacturers offer replacement parts, which makes it easy to maintain the integrity of the drag chain system.

In conclusion, plastic drag chain cable carriers are an essential component in modern industrial automation. Their role in safeguarding cables and hoses from damage, combined with their adaptability and ease of use, makes them a preferred choice for many manufacturers looking to enhance the efficiency and longevity of their equipment. By investing in high-quality drag chains, businesses can ensure smoother operations and reduce downtime due to cable management issues.