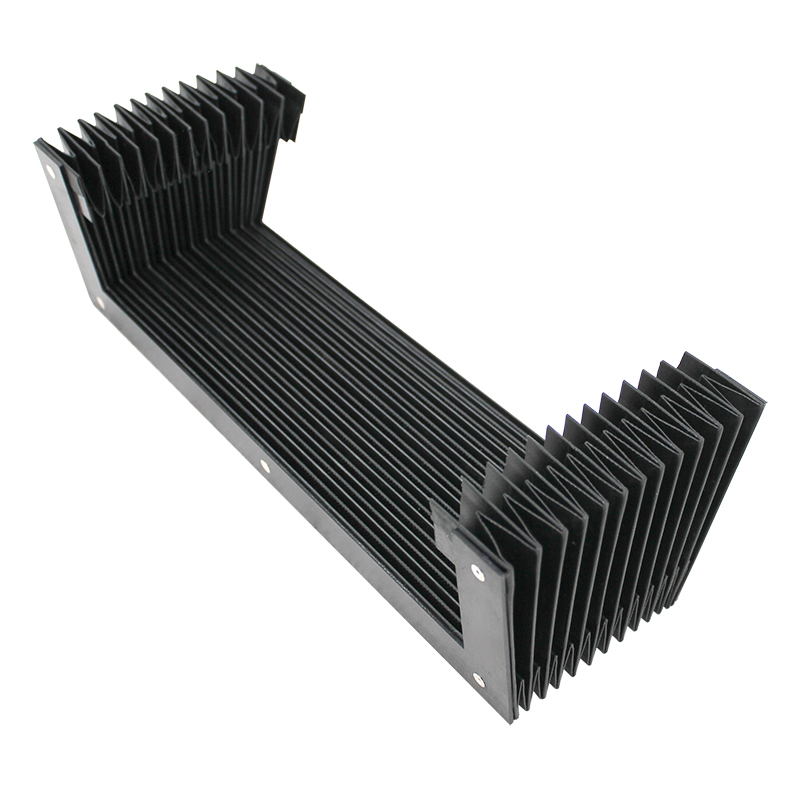

plastic flexible cable carrier chain

The Advantages of Plastic Flexible Cable Carrier Chains

In a world where technology is constantly evolving, the demand for effective and efficient solutions in machinery and automation has never been greater. One critical component in this realm is the flexible cable carrier chain, specifically those made from plastic. These innovative systems enhance organization, protection, and mobility of cables and hoses in a variety of applications. This article will explore the unique features, benefits, and applications of plastic flexible cable carrier chains.

What is a Plastic Flexible Cable Carrier Chain?

A plastic flexible cable carrier chain is a specialized tool designed to organize and move cables and hoses in mechanical systems. Composed of strong, durable plastic materials, these chains provide reliable protection for vital components while allowing for smooth motion. The chains are made up of interconnected links that create a trough-like structure, allowing cables and hoses to be routed through them. As these cables need to flex and bend in various directions, the design of the carrier chain is essential for maintaining a continuous operation without wear or damage.

Benefits of Using Plastic Flexible Cable Carrier Chains

1. Durability and Strength Plastic carrier chains are designed to withstand various environmental challenges, including extreme temperatures, moisture, and chemicals. Unlike metal alternatives, they are often lighter, which reduces the overall weight of the moving components and improves the efficiency of the machinery.

2. Flexibility and Customization These chains can be tailored to accommodate specific requirements, including different lengths, shapes, and sizes. This flexibility allows designers to create custom configurations that suit the distinct needs of their applications, whether in manufacturing, robotics, or automotive industries.

3. Reduced Maintenance Costs The use of plastic materials translates into less friction and wear on cables, leading to a significant reduction in maintenance requirements over time. Fewer breakdowns and less frequent replacements contribute to overall cost savings for businesses.

4. Enhanced Safety With cables and hoses neatly organized within these chains, the risk of tangling or damage is minimized. This enhanced safety feature not only protects the components but also provides a safer working environment for personnel, reducing the likelihood of accidents caused by exposed or loose cables.

plastic flexible cable carrier chain

5. Noise Reduction The design of plastic carrier chains often incorporates noise-dampening features that can significantly reduce operational noise. This is particularly beneficial in environments such as manufacturing plants where excessive noise can impede communication and result in worker fatigue.

Applications of Plastic Flexible Cable Carrier Chains

Plastic flexible cable carrier chains have a wide range of applications across various industries

- Automated Manufacturing These chains are prevalent in robotic arms, conveyor systems, and other automated machinery where the movement of cables is continuous and complex. They facilitate consistent movement without the risk of wear or damage.

- Aerospace and Automotive In these highly regulated industries, cable management is essential for ensuring reliability and safety. Plastic carrier chains are used in assembly lines, testing equipment, and inside machinery where space constraints require a compact yet effective solution.

- Medical Equipment In the medical field, where precision and hygiene are paramount, plastic flexible cable carrier chains are employed to manage connections in diagnostic machines, surgical instruments, and imaging equipment.

- Construction Equipment Heavy machinery often operates in harsh environments. Using robust plastic carrier chains allows for the safe movement and management of cables in various construction equipment, ensuring reliable performance under challenging conditions.

Conclusion

Plastic flexible cable carrier chains represent a vital solution for managing cables and hoses across numerous industries. Their durability, flexibility, and ability to reduce maintenance costs make them an attractive choice for manufacturers and engineers seeking efficient, reliable, and safe cable management solutions. As technology progresses and industries seek innovative ways to improve operations, the presence and importance of plastic cable carrier chains will likely continue to grow, shaping the future of automated systems. These tools not only enhance performance but also contribute to a safer and more organized work environment.