plastic flexible cable carrier chain

The Advantages of Plastic Flexible Cable Carrier Chains

In the realm of modern industrial automation and robotics, the need for efficient and reliable systems is paramount. One essential component that has gained significant traction is the plastic flexible cable carrier chain. This innovation not only enhances the performance of machinery but also addresses many challenges faced by engineers and designers in connecting moving parts.

What is a Plastic Flexible Cable Carrier Chain?

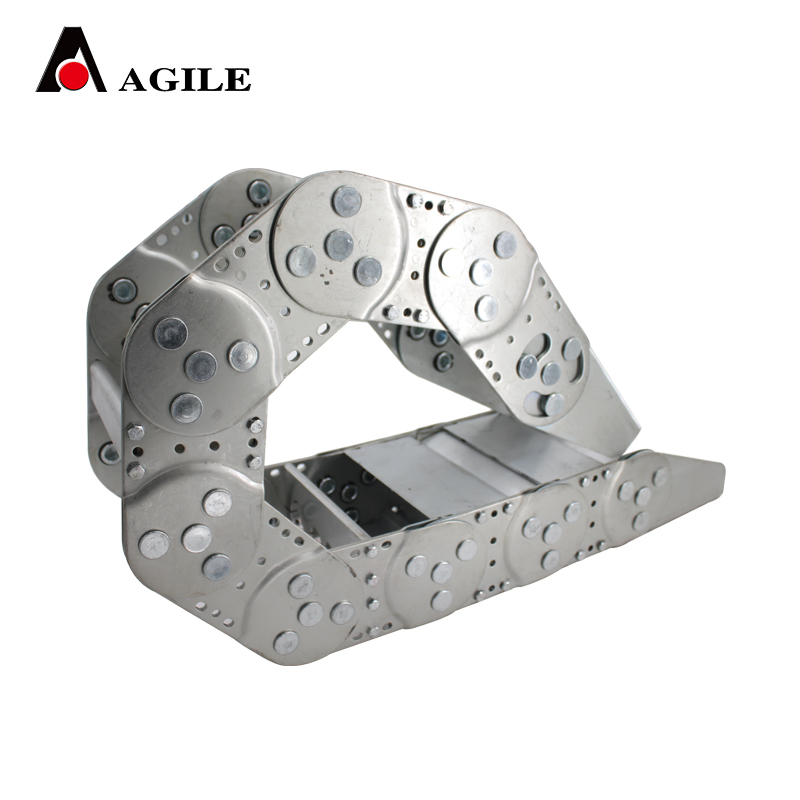

A plastic flexible cable carrier chain is a modular system designed to hold and protect cables and hoses in applications where flexible movement is required. These chains are constructed from high-quality plastic materials, enabling them to be lightweight yet durable. They are typically used in environments where traditional rigid conduits cannot sustain the dynamic movement of machinery—such as robotic arms, conveyor systems, and automated production lines.

Advantages of Plastic Flexible Cable Carrier Chains

1. Reduced Friction and Wear One of the most significant benefits of using plastic cable carrier chains is their ability to minimize friction between moving parts. The smooth inner surface of the carriers allows for easy cable passage, reducing wear on the cables themselves. This is particularly important in environments where repetitive movements occur, as it directly influences the lifespan of the cables and hoses being utilized.

2. Lightweight Design Plastic materials are inherently lighter than metals, which allows for a more lightweight chain solution. This reduced weight is crucial in applications such as robotics and automation, where every gram counts in terms of efficiency and speed. The lightweight design also means that less force is required to move the carrier chain, contributing to overall energy savings in industrial operations.

plastic flexible cable carrier chain

3. Flexibility and Customization Plastic flexible cable carrier chains can be easily customized to fit the specific needs of an application. They can be manufactured in various lengths, widths, and configurations, making them incredibly versatile. Additionally, various accessories such as mounting brackets and covers can be integrated to suit specific operational requirements.

4. Resistance to Chemicals and Environmental Factors Many plastic flexible cable carrier chains are designed with resistance to a range of chemicals, oils, and environmental conditions. This durability ensures that they can be used in various industries, including food processing, pharmaceuticals, and manufacturing, where exposure to harsh substances is common. Moreover, some plastics are UV-resistant, making them suitable for outdoor applications.

5. Lower Noise Levels In many industrial settings, noise reduction is a crucial factor for operator comfort and safety. The design of plastic chains helps to absorb vibrations and minimize noise during operation. This advantage can lead to a more pleasant working environment and can even reduce the potential risk of hearing damage for workers over extended periods.

6. Cost-Effectiveness Compared to metal alternatives, plastic flexible cable carrier chains can offer significant cost savings. They are typically less expensive to produce and maintain, leading to lower overall operating costs. Their durability and flexibility also mean fewer replacements are needed, which further contributes to cost-effectiveness.

Conclusion

The introduction of plastic flexible cable carrier chains represents a significant advancement in the world of industrial design and automation. With their unique combination of lightweight design, flexibility, resistance to environmental factors, and reduced noise levels, these chains are redefining how engineers approach the challenge of cable management in dynamic systems. As industries continue to evolve and prioritize efficiency, the role of plastic flexible cable carrier chains is set to become increasingly vital, paving the way for innovations in machinery and automation.