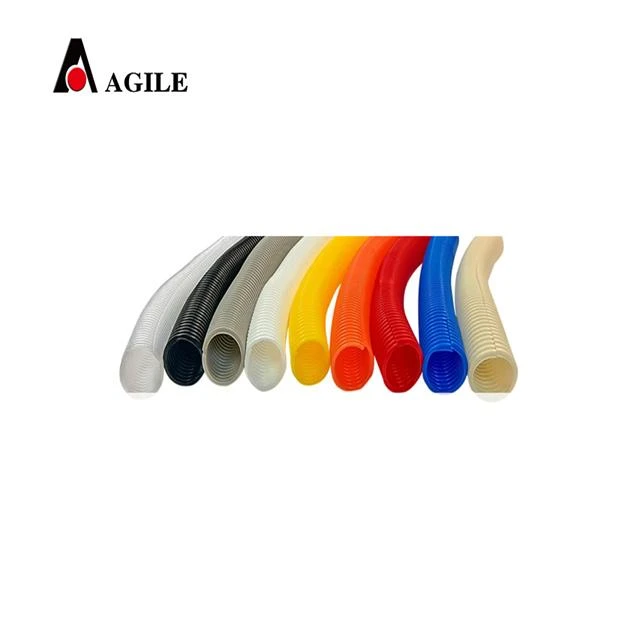

corrugated loom tubing

Plastic split loom tubing, a seemingly modest product, plays an instrumental role in organizing and protecting the wiring in various settings, ranging from automotive applications to home office setups. Plastic split loom tubes, also known as corrugated wire loom tubing, are designed to safeguard wires from abrasion, punctures, and other environmental hazards. For businesses and DIY enthusiasts alike, understanding the unique qualities and uses of plastic split loom can be transformative, not only for the longevity and aesthetics of their projects but also for ensuring efficiency and safety.

On construction sites, this tubing is invaluable for organizing and protecting cables and wires in harsh environments. Additionally, audio-visual technicians often leverage plastic split loom tubing to manage and protect the extensive cabling in performance and broadcasting settings, where cable integrity can impact performance quality. Installing Plastic Split Loom Tubing Tips for Optimal Use When it comes to installation, a few best practices can maximize the protective benefits of split loom tubing. It is important to select the correct size for your needs; the tubing should fit snugly around the wires to be effective without being too tight as to restrict flexibility or airflow. A clean working environment and properly trimmed wire ends can prevent snags or damage to the tubing during installation. For added security, the ends of the tubing can be fixed with electrical tape or cable ties to prevent accidental slippage or exposure, thus maintaining the integrity of the enclosed wires. Choosing a Reliable Supplier Quality Assurance and Safety Investing in high-quality plastic split loom tubing from a reputable supplier ensures longevity and performance. Suppliers with a proven track record and expertise in cable management solutions offer peace of mind, knowing that their products meet stringent industry standards for safety and durability. Additionally, these companies often provide valuable resources and support, from detailed product specifications to personalized recommendations tailored to specific applications, demonstrating their authority and trustworthiness in the marketplace. To conclude, plastic split loom tubing is not merely a product; it is a critical component in modern wiring and cabling systems across multiple domains. By integrating this modest yet mighty innovation, users can yield improved safety, enhanced organization, and longer-lasting protection for their wiring solutions, all while contributing to more environmentally responsible practices.

On construction sites, this tubing is invaluable for organizing and protecting cables and wires in harsh environments. Additionally, audio-visual technicians often leverage plastic split loom tubing to manage and protect the extensive cabling in performance and broadcasting settings, where cable integrity can impact performance quality. Installing Plastic Split Loom Tubing Tips for Optimal Use When it comes to installation, a few best practices can maximize the protective benefits of split loom tubing. It is important to select the correct size for your needs; the tubing should fit snugly around the wires to be effective without being too tight as to restrict flexibility or airflow. A clean working environment and properly trimmed wire ends can prevent snags or damage to the tubing during installation. For added security, the ends of the tubing can be fixed with electrical tape or cable ties to prevent accidental slippage or exposure, thus maintaining the integrity of the enclosed wires. Choosing a Reliable Supplier Quality Assurance and Safety Investing in high-quality plastic split loom tubing from a reputable supplier ensures longevity and performance. Suppliers with a proven track record and expertise in cable management solutions offer peace of mind, knowing that their products meet stringent industry standards for safety and durability. Additionally, these companies often provide valuable resources and support, from detailed product specifications to personalized recommendations tailored to specific applications, demonstrating their authority and trustworthiness in the marketplace. To conclude, plastic split loom tubing is not merely a product; it is a critical component in modern wiring and cabling systems across multiple domains. By integrating this modest yet mighty innovation, users can yield improved safety, enhanced organization, and longer-lasting protection for their wiring solutions, all while contributing to more environmentally responsible practices.