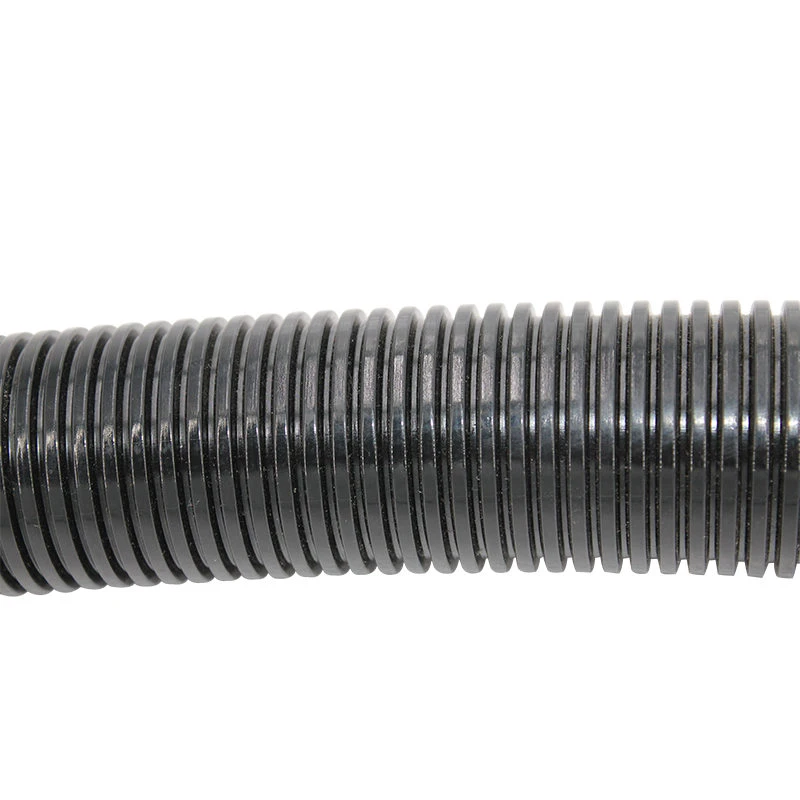

polyethylene split loom

Understanding Polyethylene Split Loom An Essential Component in Cable Management

In today's rapidly advancing technological landscape, the importance of efficient cable management cannot be overstated. One of the unsung heroes in this domain is the polyethylene split loom, a versatile solution that protects and organizes cables and wires in various applications.

Polyethylene split loom tubing is made from high-density polyethylene (HDPE), a durable and flexible material known for its strength and resistance to wear and tear. This tubing features a split along its length, allowing easy insertion of multiple cables while providing excellent protection from abrasion, cuts, and environmental damage. Its design ensures that cables remain organized, reducing the risk of tangling and errors during installation or maintenance.

One of the primary benefits of using polyethylene split loom is its adaptability. It is widely utilized in automotive applications, home wiring, industrial machinery, and even in telecommunications. This versatility stems from its ability to accommodate various wire sizes and types, making it a go-to choice for engineers and technicians looking to streamline their work.

polyethylene split loom

Moreover, polyethylene split loom is designed to withstand extreme temperatures, varying from -40°F to 200°F (-40°C to 93°C), making it suitable for both indoor and outdoor applications. Additionally, its resistance to moisture, chemicals, and UV exposure enhances its longevity, further solidifying its role as a reliable protective measure for cables in different environments.

Installation of polyethylene split loom is straightforward. Users can cut the material to the desired length, insert the cables, and secure the ends if necessary. Its lightweight nature does not add significant bulk to the wiring system, which is particularly beneficial in applications where space is at a premium.

From a safety standpoint, using split loom can help prevent electrical shorts, reduce wear on cables, and minimize the risk of accidental damage. By providing a protective barrier, it ensures that the cables remain functional for longer periods, reducing the need for frequent replacements and ultimately saving costs.

In conclusion, polyethylene split loom tubing epitomizes practicality and durability in cable management solutions. Its myriad advantages, including protection from environmental factors, ease of installation, and versatility across various industries, make it an invaluable asset in modern wiring practices. As technology continues to evolve, the role of such protective solutions becomes increasingly critical, ensuring that our wired world remains safe and efficient.