Protective Bellow Cover Solutions for Enhanced Equipment Longevity and Performance

Understanding Protective Bellow Covers Essential Components for Machinery and Equipment

In the realm of machinery and equipment operation, protective bellow covers play a vital role in ensuring the longevity and efficiency of mechanical systems. These innovative components serve as barriers that safeguard various moving parts from environmental contaminants, debris, moisture, and physical impact. In this article, we will delve into the significance of protective bellow covers, exploring their design, materials, applications, and advantages in industrial settings.

What are Protective Bellow Covers?

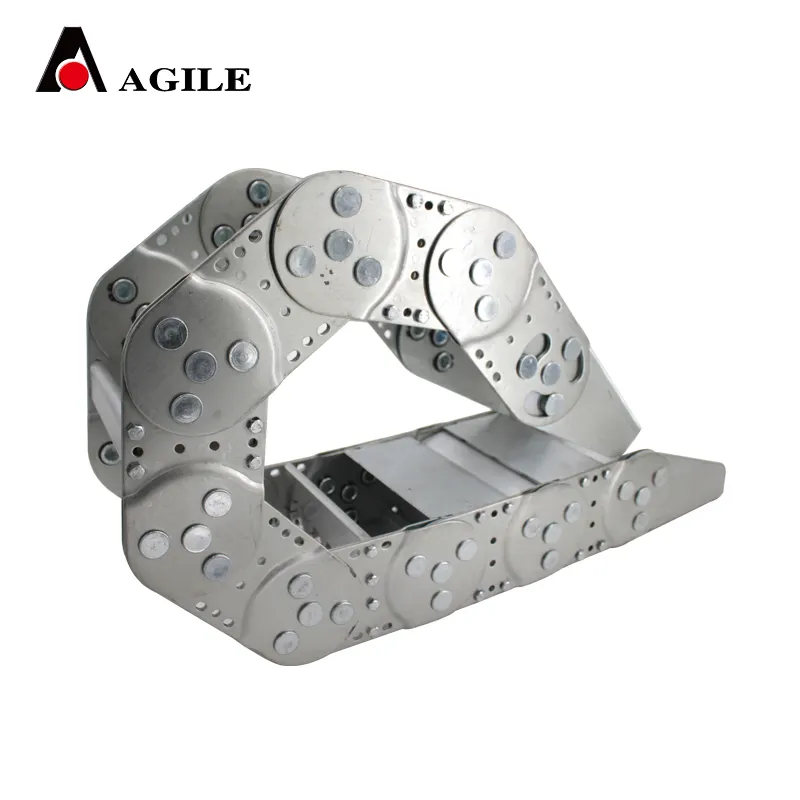

Protective bellow covers, often referred to as bellows or bellows covers, are flexible, accordion-style protective sleeves made from materials such as rubber, polyvinyl chloride (PVC), silicone, or other durable polymers. These covers are designed to enclose and shield components like linear slides, rods, valves, and machinery joints, creating a barrier against outside elements that could lead to wear and tear.

Design and Construction

The design of protective bellow covers is crucial for their effectiveness. Typically, they feature a series of folds that allow for flexibility and extension while maintaining a tight enclosure around the machinery component. The geometry of the bellows ensures that they can expand and contract as needed, accommodating the movements of the machinery while providing a snug protective fit.

When it comes to materials, manufacturers select them based on the specific environment in which the equipment operates. For instance, high-temperature applications may require silicone bellows, while environments prone to chemical exposure might benefit from PVC or fluoropolymer materials that resist corrosive substances. Additionally, some bellows are reinforced with fabric or metal for extra durability.

Applications of Protective Bellow Covers

Protective bellow covers find application in a wide range of industries, including

1. Manufacturing and Machinery They protect moving parts of CNC machines, lathes, and milling machines from metal shavings, coolant, and dust. This is critical for maintaining precision and reducing maintenance costs.

2. Automotive Industry In automotive manufacturing and maintenance, bellows are used to protect suspension components, steering joints, and driveshafts from dirt and moisture.

protective bellow cover

4. Aerospace In aerospace applications, protective bellows help prevent foreign object damage to critical components in aircraft engines and other systems.

5. Medical Equipment In the medical field, bellows protect delicate machinery in devices like surgical robots and diagnostic machines, ensuring optimal performance while maintaining hygiene standards.

Advantages of Using Protective Bellow Covers

The benefits of utilizing protective bellow covers in various applications are numerous

1. Enhanced Durability By shielding components from dust, grime, and moisture, bellows extend the lifespan of machinery, reducing the need for frequent repairs or replacements.

2. Improved Reliability Protecting mechanical parts from external elements enhances overall reliability and reduces the risk of unexpected breakdowns, which can lead to costly downtime.

3. Cost-Effectiveness Although there is an initial investment in installing protective bellow covers, the long-term savings on maintenance costs and increased productivity far outweigh this initial expense.

4. Customizability Many manufacturers offer bespoke bellow designs tailored to specific machinery demands, allowing for optimal integration and performance.

5. Safety By containing lubricants and preventing debris accumulation, protective bellows contribute to a safer working environment, minimizing the risk of accidents due to equipment failure.

Conclusion

In conclusion, protective bellow covers are indispensable components in modern machinery and equipment across various industries. Their ability to safeguard sensitive parts from environmental damage not only extends equipment life but also ensures uninterrupted operation and safety. As technology advances and industries evolve, the importance of these protective elements will continue to grow, driving innovation in their design and materials to meet the ever-changing demands of industrial applications. By recognizing their value, organizations can enhance productivity and reliability, making protective bellow covers an essential pillar in equipment maintenance strategies.