protective bellows covers

Protective Bellows Covers An Essential Shield for Machinery

In the realm of industrial machinery and equipment, the significance of protective components cannot be overstated. Among these, protective bellows covers stand out as crucial elements designed to safeguard vital machine parts from abrasive materials, moisture, dust, and other environmental hazards. These versatile covers are engineered to extend the life of machinery while maintaining optimal operational efficiency.

Understanding Protective Bellows Covers

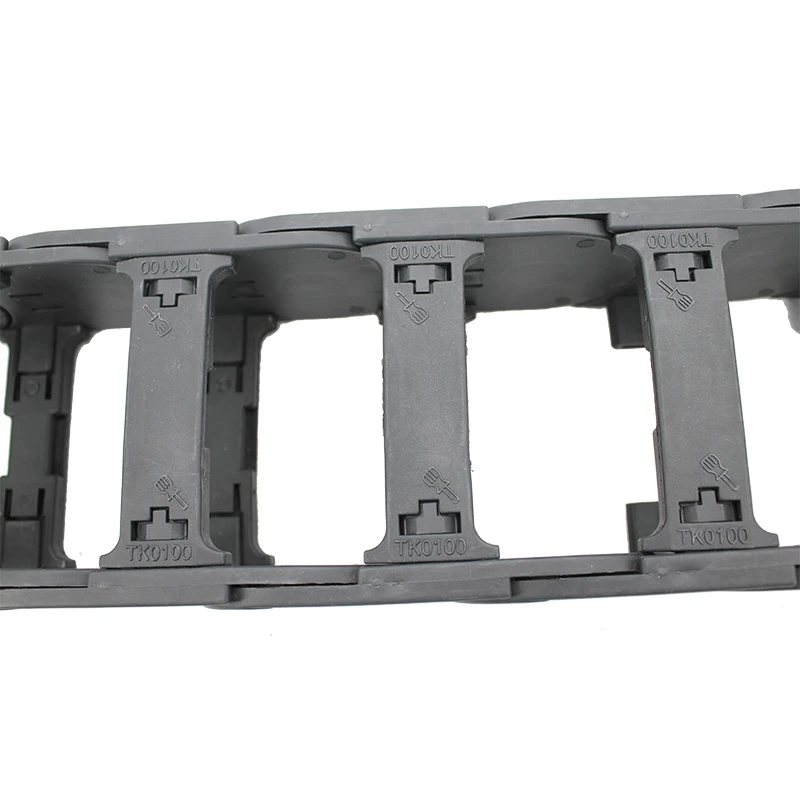

Protective bellows covers, often referred to simply as bellows, are flexible, accordion-like structures typically made from materials such as rubber, polyurethane, or fabric. They are constructed to encapsulate moving components of machinery, such as pistons, shafts, and linear guides, providing a shield against contaminants that can lead to wear and tear. Their design allows for considerable movement, making them ideal for dynamic environments where parts frequently undergo extensive motion.

Applications Across Industries

The utility of protective bellows covers transcends various sectors, including manufacturing, automotive, aerospace, and robotics. In manufacturing, for instance, these covers are vital for machine tools, such as lathes and milling machines. They prevent the ingress of swarf (metal shavings) and cutting fluids, which can degrade precision components. In the automotive industry, bellows are used in steering columns and suspension systems to safeguard sensitive parts from road debris and moisture.

In the aerospace sector, bellows covers are critical in protecting actuators and joints in aircraft systems, ensuring reliability under extreme conditions. Furthermore, in robotics, they guard against dust and particulates that could hinder performance, thereby enhancing the longevity and reliability of robotic arms and similar equipment.

Benefits of Using Protective Bellows Covers

protective bellows covers

The primary advantage of protective bellows covers lies in their ability to extend the lifespan of machinery. By acting as a barrier against contaminants, they reduce the risk of part failure due to abrasion and corrosion. This not only minimizes downtime caused by repairs but also lowers maintenance costs, leading to significant savings in the long run.

Additionally, these covers enhance operational safety. By containing moving parts and preventing exposure, they reduce the likelihood of accidents that can arise from the entanglement of clothing or other objects with machinery. This is especially important in settings where high-speed operations occur.

Customization and Material Selection

One of the key features of protective bellows covers is their adaptability. Manufacturers can customize these products to fit specific machinery applications, taking into account factors such as size, shape, and the degree of motion required. Additionally, the choice of materials is critical, as different environments may require different levels of resistance to chemicals, temperatures, or UV exposure.

For instance, in environments where chemicals are prevalent, selecting a bellows made of chemical-resistant materials is crucial. Similarly, in high-temperature applications, materials that can withstand heat without degrading are essential.

Conclusion

In conclusion, protective bellows covers play an indispensable role in the longevity and reliability of machinery across various industries. By offering protection against contamination and environmental factors, they contribute to enhanced operational efficiency and safety. As technology advances and industries evolve, the demand for customized and durable bellows covers will likely grow, underscoring their importance in modern machinery and equipment design. Investing in high-quality protective bellows covers is a proactive approach to maintaining machinery, ultimately leading to increased productivity and reduced operational costs. As industrial applications continue to expand, the need for effective protective solutions like bellows covers will remain a priority for engineers and manufacturers alike.