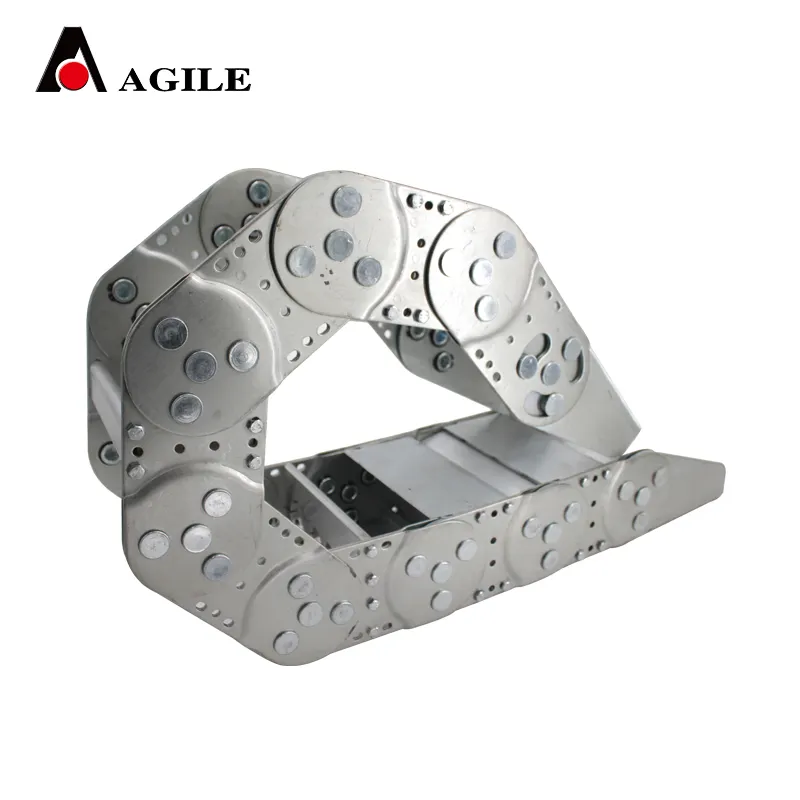

protective wire loom

Navigating the intricate world of protective wire looms can be daunting for those new to electrical applications. However, understanding their critical role in safeguarding wiring systems is essential for both experienced technicians and DIY enthusiasts.

Heat resistance is non-negotiable for applications exposed to high temperatures. High-temp wire looms, often made from specialized nylon, can withstand significant thermal stress, safeguarding wires in engine bays or industrial machinery. Their ability to maintain structural integrity under extreme conditions assures users of their performance reliability. When it comes to installation, simplicity and efficiency are paramount. Pre-slit wire looms require minimal effort and time, making them a practical choice for quick retrofits. Moreover, color-coding options facilitate easy identification and troubleshooting of wiring systems, reducing maintenance time and improving system management. Matching protective wire looms to specific industry requirements also involves adhering to regulatory standards. For instance, compliance with UL (Underwriters Laboratories) standards ensures that the looms meet stringent safety criteria. Such certifications not only guarantee quality but also build trust with consumers, reinforcing the product's reliability. The benefits do not end at protection. Employing wire looms also streamlines the aesthetic aspect of cable management, providing a cleaner, more professional look to electrical installations. In a world where visual clutter can be as detrimental as technical inefficiency, wire looms offer a dual advantage. In conclusion, mastering the nuances of protective wire looms involves a combination of selecting suitable materials, dimensions, and designs tailored to specific applications. The investment in high-quality wire looms pays off through enhanced system performance, increased safety, and reduced maintenance costs. As technology evolves, staying informed about advancements in wire loom technology and standards becomes imperative for both personal and professional applications. Whether in the heart of a bustling factory or the confines of a hobbyist's garage, wire looms stand as silent guardians, ensuring order, efficiency, and safety in our wired world.

Heat resistance is non-negotiable for applications exposed to high temperatures. High-temp wire looms, often made from specialized nylon, can withstand significant thermal stress, safeguarding wires in engine bays or industrial machinery. Their ability to maintain structural integrity under extreme conditions assures users of their performance reliability. When it comes to installation, simplicity and efficiency are paramount. Pre-slit wire looms require minimal effort and time, making them a practical choice for quick retrofits. Moreover, color-coding options facilitate easy identification and troubleshooting of wiring systems, reducing maintenance time and improving system management. Matching protective wire looms to specific industry requirements also involves adhering to regulatory standards. For instance, compliance with UL (Underwriters Laboratories) standards ensures that the looms meet stringent safety criteria. Such certifications not only guarantee quality but also build trust with consumers, reinforcing the product's reliability. The benefits do not end at protection. Employing wire looms also streamlines the aesthetic aspect of cable management, providing a cleaner, more professional look to electrical installations. In a world where visual clutter can be as detrimental as technical inefficiency, wire looms offer a dual advantage. In conclusion, mastering the nuances of protective wire looms involves a combination of selecting suitable materials, dimensions, and designs tailored to specific applications. The investment in high-quality wire looms pays off through enhanced system performance, increased safety, and reduced maintenance costs. As technology evolves, staying informed about advancements in wire loom technology and standards becomes imperative for both personal and professional applications. Whether in the heart of a bustling factory or the confines of a hobbyist's garage, wire looms stand as silent guardians, ensuring order, efficiency, and safety in our wired world.