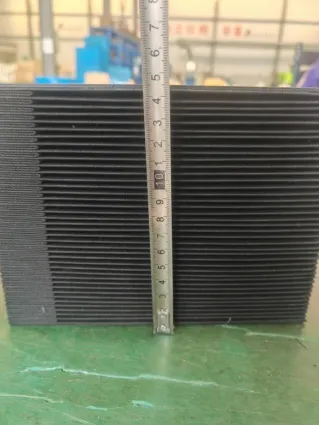

metal chip conveyor

Scraper chip conveyors are vital components in the manufacturing landscape, especially in industries where metalworking and machining are predominant. These conveyors effectively manage and transport metal chips away from the workplace, promoting safety and enhancing productivity. Their evolution has seen a tremendous overlap with technological advancements, making them not just an auxiliary but a necessary component of modern workshops.

In the ever-evolving industrial landscape, scraper chip conveyors are continuously being optimized. Recent innovations focus on reducing maintenance costs, enhancing energy efficiency, and integrating IoT for predictive maintenance. With environmental consciousness gaining momentum, the recyclability of the chips collected by these conveyors is being prioritized, allowing industries to adopt sustainable practices. Another innovative direction is the incorporation of sensors and automated controls, which allow real-time monitoring and adjustments. Smart conveyor systems can now predict clogging and alert operators before a major system upset occurs, thereby ensuring continuous operation. The future potential of scraper chip conveyors lies in their adaptability and smart integration into Industry 4.0 frameworks. With the push towards smart factories, there is a growing trend to have these conveyors seamlessly connected with other machines via IoT and AI-driven platforms. Such integration optimizes the workflow and ensures that scrap management is not an afterthought but a streamlined part of the production process. In essence, scraper chip conveyors are more than auxiliary systems. They embody a blend of practicality, specialization, authority, and reliability, carving out their space as indispensable to modern manufacturing efficiencies. As industries further pivot towards automation and optimization, scraper chip conveyors will undoubtedly continue to innovate, aligning with both technological advancements and the need for sustainable operations.

In the ever-evolving industrial landscape, scraper chip conveyors are continuously being optimized. Recent innovations focus on reducing maintenance costs, enhancing energy efficiency, and integrating IoT for predictive maintenance. With environmental consciousness gaining momentum, the recyclability of the chips collected by these conveyors is being prioritized, allowing industries to adopt sustainable practices. Another innovative direction is the incorporation of sensors and automated controls, which allow real-time monitoring and adjustments. Smart conveyor systems can now predict clogging and alert operators before a major system upset occurs, thereby ensuring continuous operation. The future potential of scraper chip conveyors lies in their adaptability and smart integration into Industry 4.0 frameworks. With the push towards smart factories, there is a growing trend to have these conveyors seamlessly connected with other machines via IoT and AI-driven platforms. Such integration optimizes the workflow and ensures that scrap management is not an afterthought but a streamlined part of the production process. In essence, scraper chip conveyors are more than auxiliary systems. They embody a blend of practicality, specialization, authority, and reliability, carving out their space as indispensable to modern manufacturing efficiencies. As industries further pivot towards automation and optimization, scraper chip conveyors will undoubtedly continue to innovate, aligning with both technological advancements and the need for sustainable operations.