Screw Chip Conveyor - Efficient Chip Removal Solutions

The Importance of Screw Chip Conveyors in Modern Manufacturing

In the realm of modern manufacturing, efficient material handling is crucial for optimizing productivity and ensuring streamlined operations. One such innovation that has gained significant traction is the screw chip conveyor. This specialized equipment is designed to transport metal chips, shavings, and other waste materials generated during machining processes, efficiently and effectively.

A screw chip conveyor typically consists of a helical screw blade mounted within a tube or trough. As the screw rotates, it moves the chips along the length of the conveyor. This method of transportation is particularly advantageous in machining facilities where metalworking processes produce a large volume of chips, such as milling, turning, and grinding. Traditional methods of chip removal can be cumbersome and often lead to operational delays; screw chip conveyors offer a reliable solution that minimizes downtime.

One of the key benefits of screw chip conveyors is their ability to handle various types of materials. Whether dealing with ferrous or non-ferrous metals, these conveyors can be customized to meet specific requirements. They can be designed to accommodate different chip sizes and shapes, making them versatile for various machining operations. Additionally, the enclosed design of screw chip conveyors prevents the chips from spilling onto the shop floor, keeping the workspace tidy and reducing the risk of accidents.

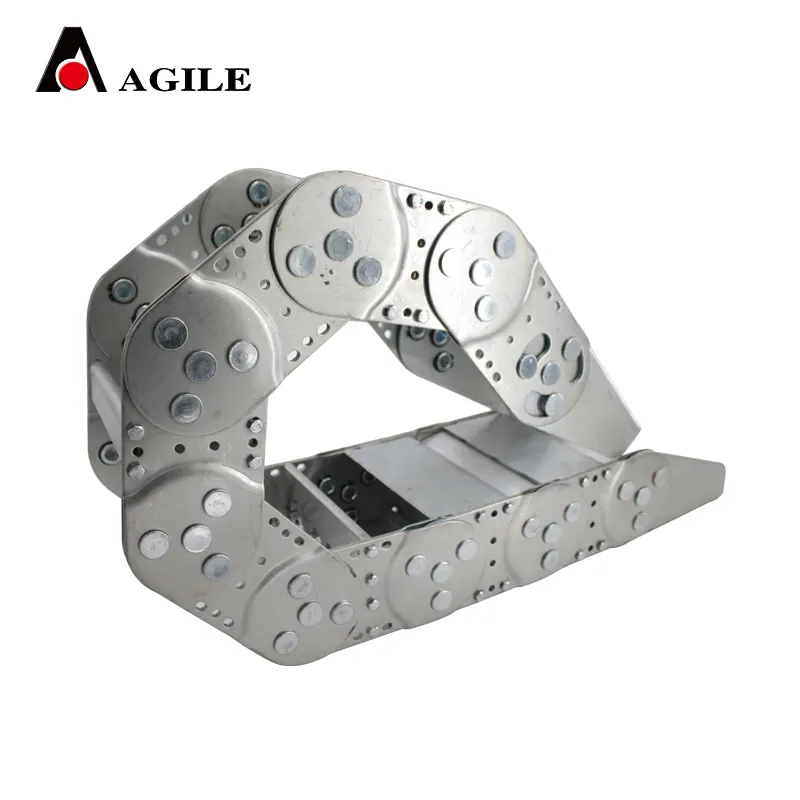

screw chip conveyor

Moreover, screw chip conveyors can be integrated with other systems in the manufacturing process. For instance, they can be connected to chip crushers or shredders, which further reduce the volume of waste material before it is transported to disposal or recycling. By incorporating such systems, manufacturers can improve their sustainability efforts, as reduced waste can lead to lower disposal costs and a smaller environmental footprint.

Maintenance is another critical aspect of screw chip conveyors. They are generally designed for durability and longevity, but regular maintenance is essential to ensure optimal performance. Lubrication of moving parts, inspection of the screw for wear, and cleaning of the conveyor trough are routine tasks that help in extending the lifespan of the equipment. By investing in proper maintenance, manufacturers can avoid costly repairs and ensure continuous operation.

In summary, screw chip conveyors play a vital role in modern machining environments by efficiently managing metal waste, enhancing productivity, and supporting sustainability initiatives. As manufacturing processes continue to evolve, the need for innovative material handling solutions like screw chip conveyors will become increasingly important. By adopting this technology, manufacturers can optimize their operations, minimize waste, and maintain a safe working environment. As we look to the future, it is clear that screw chip conveyors will remain an integral component of efficient manufacturing practices.