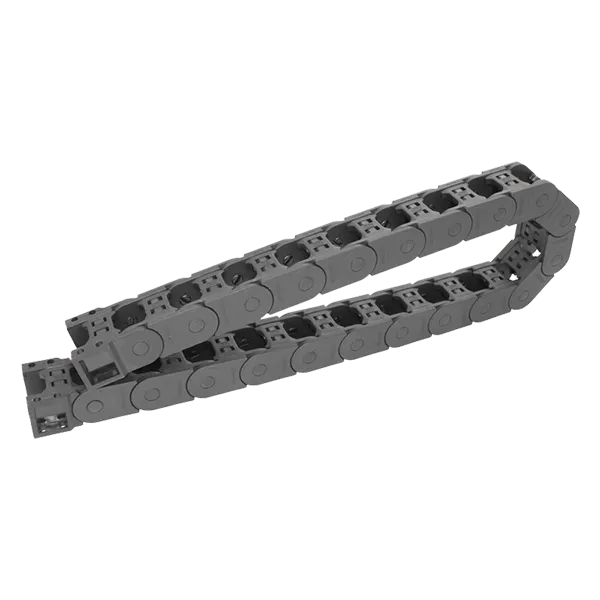

18*50 mm MT small size semi enclosed cable chain for printer

Semi-enclosed cable chains, often known as semi-enclosed drag chains or energy chains, have been pivotal in streamlining industrial automation processes. Their design facilitates the protection and guidance of cables, hoses, and hydraulic lines, ultimately enhancing the longevity and functionality of mechanical systems. With the rise in smart manufacturing and automation, the importance of selecting the right cable management system has surged, and semi-enclosed cable chains exemplify a blend of innovation and practicality.

Trust in product quality and supplier reliability is another cornerstone in the selection process. Established manufacturers often provide extensive documentation and compliance certificates, authenticating the robustness and reliability of their semi-enclosed cable chains. This transparency fosters trust and allows users to make informed decisions backed by empirical data and industry standards. Moreover, real-world testimonials and case studies serve as reliable indicators of product performance. Companies that have integrated semi-enclosed cable chains into their systems often report significant enhancements in cable management efficiency, alongside measurable reductions in machine downtime and maintenance costs. These authentic narratives, coupled with technical data, consolidate the reputation of semi-enclosed cable chains as a prudent investment in high-performance environments. In summary, semi-enclosed cable chains offer a harmonious blend of protection, flexibility, and durability crucial for modern industrial applications. Their design, guided by expert engineering, addresses both operational challenges and technical constraints effectively. Anchored by principles of trust and authority, semi-enclosed cable chains emerge as pivotal components in the pursuit of enhanced manufacturing efficacy and reliability. Thus, their role in advancing automation, efficiency, and sustainability within industrial landscapes is undeniable.

Trust in product quality and supplier reliability is another cornerstone in the selection process. Established manufacturers often provide extensive documentation and compliance certificates, authenticating the robustness and reliability of their semi-enclosed cable chains. This transparency fosters trust and allows users to make informed decisions backed by empirical data and industry standards. Moreover, real-world testimonials and case studies serve as reliable indicators of product performance. Companies that have integrated semi-enclosed cable chains into their systems often report significant enhancements in cable management efficiency, alongside measurable reductions in machine downtime and maintenance costs. These authentic narratives, coupled with technical data, consolidate the reputation of semi-enclosed cable chains as a prudent investment in high-performance environments. In summary, semi-enclosed cable chains offer a harmonious blend of protection, flexibility, and durability crucial for modern industrial applications. Their design, guided by expert engineering, addresses both operational challenges and technical constraints effectively. Anchored by principles of trust and authority, semi-enclosed cable chains emerge as pivotal components in the pursuit of enhanced manufacturing efficacy and reliability. Thus, their role in advancing automation, efficiency, and sustainability within industrial landscapes is undeniable.