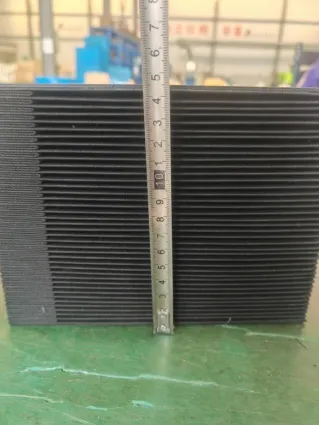

semi enclosed cable chain

Semi-enclosed cable chains have become an essential component in numerous industrial applications, offering a balance between protection and flexibility. These chains safeguard cables and hoses from external elements while allowing movement, making them indispensable in a variety of settings, from manufacturing to robotics.

End users trust these cable chains, finding that manufacturers who produce them have a consistent track record in innovation and adherence to stringent safety standards. Many of these manufacturers are prominent in their field, sharing a reputation for high-quality production that marks their products out as reliable and long-lasting. When it comes to installation, semi-enclosed cable chains offer ease and versatility. They are engineered for straightforward assembly and integration into existing systems. Their modular nature allows for customization, suiting an array of applications no matter how specific the requirements. This flexibility not only underscores their practicality but also amplifies their usability across a multitude of sectors—be it to adapt to specific spatial constraints or to facilitate rapid deployment in time-sensitive projects. The expertise of companies producing semi-enclosed cable chains is reflected in the thoughtful features they embed in their products. Advances such as noise dampeners, high-speed capabilities, and resistance to extreme temperatures are common among leading models, illustrating an understanding of the varied demands these chains meet across different industries. Ultimately, the choice of semi-enclosed cable chains rests on their proven track record and the credible endorsements from professionals who regularly employ these systems. Their continued use in transport systems, CNC machinery, and automated production lines highlight their indispensable role in modern industry, ensuring that complex operations proceed without interruption. In summary, the appeal of semi-enclosed cable chains lies in their reliability, protective capabilities, and adaptability, ensuring they're not just a component of machinery but a cornerstone of operational integrity. This dedication to maintaining the highest standards—both in function and manufacture—cements their grid position in the toolkit of solutions for today’s technical challenges.

End users trust these cable chains, finding that manufacturers who produce them have a consistent track record in innovation and adherence to stringent safety standards. Many of these manufacturers are prominent in their field, sharing a reputation for high-quality production that marks their products out as reliable and long-lasting. When it comes to installation, semi-enclosed cable chains offer ease and versatility. They are engineered for straightforward assembly and integration into existing systems. Their modular nature allows for customization, suiting an array of applications no matter how specific the requirements. This flexibility not only underscores their practicality but also amplifies their usability across a multitude of sectors—be it to adapt to specific spatial constraints or to facilitate rapid deployment in time-sensitive projects. The expertise of companies producing semi-enclosed cable chains is reflected in the thoughtful features they embed in their products. Advances such as noise dampeners, high-speed capabilities, and resistance to extreme temperatures are common among leading models, illustrating an understanding of the varied demands these chains meet across different industries. Ultimately, the choice of semi-enclosed cable chains rests on their proven track record and the credible endorsements from professionals who regularly employ these systems. Their continued use in transport systems, CNC machinery, and automated production lines highlight their indispensable role in modern industry, ensuring that complex operations proceed without interruption. In summary, the appeal of semi-enclosed cable chains lies in their reliability, protective capabilities, and adaptability, ensuring they're not just a component of machinery but a cornerstone of operational integrity. This dedication to maintaining the highest standards—both in function and manufacture—cements their grid position in the toolkit of solutions for today’s technical challenges.