small drag chain

The Evolution and Utility of Small Drag Chains

In the realm of machinery and engineering, the efficient management of cables and hoses is paramount. One innovative solution that has garnered considerable attention is the small drag chain. This component serves as both a protective and organizational element for various lines, providing a streamlined approach to cable management.

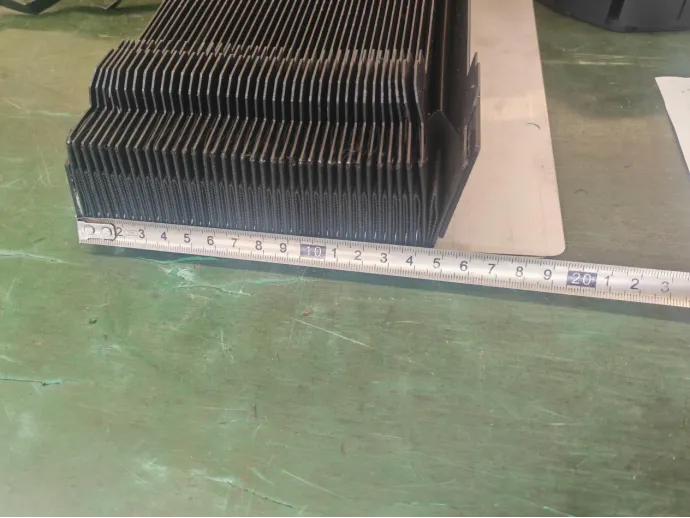

A small drag chain, often made from durable materials such as plastic or metal, is designed to carry flexible cables and hoses in a controlled manner. Its primary purpose is to prevent tangling and damage to lines that are frequently in motion. This is particularly pertinent in environments where machinery operates cyclically or continuously, as fluctuations in mobility can cause cables to wear down or become entangled, leading to costly downtime.

The design of small drag chains is a result of pioneering engineering, allowing them to accommodate diverse types of cables. From power supply lines to pneumatic hoses, a well-designed drag chain can house several cables simultaneously without compromising accessibility or functionality. The segmentation in each link allows for flexible configurations, catering to specific needs while maintaining ease of installation and modification.

small drag chain

An essential feature of small drag chains is their modest size. Their compact design means they can be used in tight spaces where larger cable management systems would be impractical. Industries such as robotics, CNC machining, and automation have benefited from these small drag chains, where precision and space efficiency are vital. Here, the small drag chain not only protects cables but also enhances the overall aesthetic and operational efficiency of the equipment.

With the advancement of technology, small drag chains have evolved in terms of materials and designs. Today’s drag chains are not only engineered for strength but also for resistance to harsh environmental conditions. From exposure to extreme temperatures to resistance against chemicals, modern small drag chains are versatile and robust. Some manufacturers even offer customizable options, allowing industries to select or design drag chains that can withstand their specific operational challenges.

Furthermore, the impact of small drag chains extends beyond their immediate function. By providing a protective route for cables, they aid in reducing maintenance costs and prolonging the lifespan of expensive electrical components. The organization provided by drag chains minimizes the risk of accidents in work environments, promoting a safer atmosphere for workers.

In summary, small drag chains are a testament to the importance of effective cable management systems in contemporary engineering practices. Their ability to streamline operations, protect vital equipment, and adapt to various industrial needs makes them an indispensable component in machinery design. As industries continue to innovate and evolve, the role of small drag chains will likely expand, further enhancing efficiency and safety in the workplace. With ongoing advancements, we can expect these small but mighty chains to play an even more significant role in the future of engineering and manufacturing.