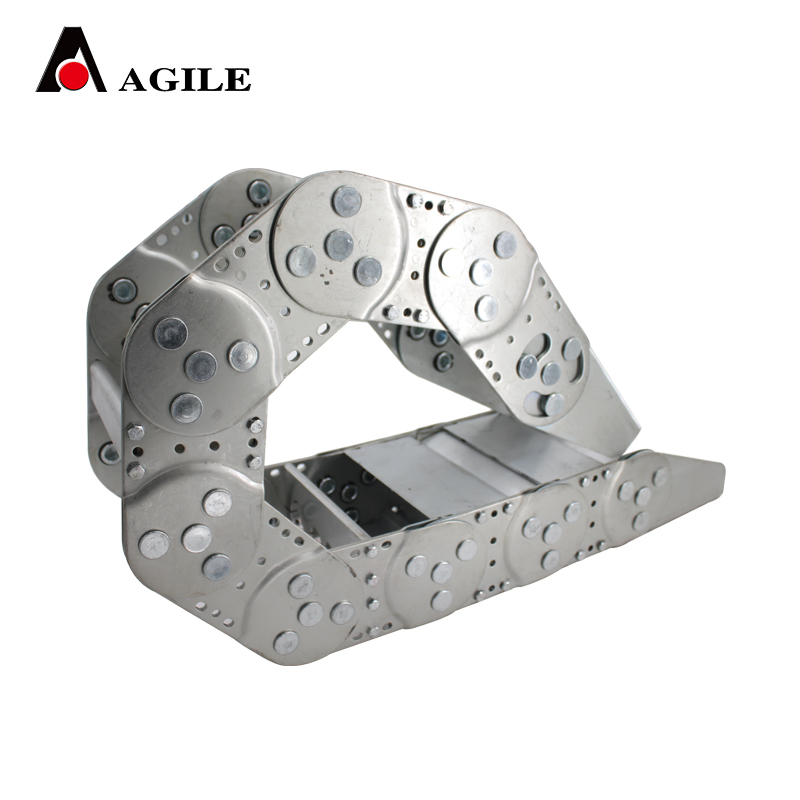

small drag chain

Understanding the Importance of Small Drag Chains in Modern Engineering

In the realm of engineering and automation, the selection of components is crucial for the efficient operation of machinery. One such component that often goes unnoticed but plays a vital role in various applications is the small drag chain. While this may seem like a minor detail, the functionality and performance of drag chains can significantly impact the efficiency, lifespan, and safety of mechanical systems.

What is a Small Drag Chain?

A small drag chain, also known as a cable carrier or energy chain, is a system designed to manage and protect cables and hoses in machinery. Typically used in environments where movement is a constant factor, drag chains are engineered to prevent tangling, wear, and damage to important electrical or pneumatic lines. These flexible chains come in various sizes and materials, tailored to meet the demands of specific applications.

Applications of Small Drag Chains

Small drag chains are prevalent across multiple industries. They are commonly found in CNC machines, pick-and-place systems, robotics, conveyor systems, and even in household appliances. For instance, in a CNC machine, drag chains guide and protect wires that connect to the moving parts, ensuring uninterrupted operation and reducing maintenance needs. In robotics, they facilitate dynamic movement by allowing cables to move freely without the risk of getting pinched or damaged.

Benefits of Using Small Drag Chains

1. Enhanced Mobility Small drag chains are designed to accommodate extensive movement. Their flexible configuration allows them to bend and twist in unison with machinery, which is crucial in systems that require precise motion control.

2. Protection of Cables and Hoses One of the primary functions of drag chains is to safeguard cables and hoses from wear and tear. By confining them within a protective enclosure, they are shielded from debris, overheating, and other environmental factors that could lead to failure.

3. Reduced Maintenance Costs Implementing drag chains can lead to significant savings on maintenance costs over time. Since cables and hoses are less likely to sustain damage, the frequency of replacements and repairs is reduced, allowing for a more streamlined operation.

small drag chain

4. Easy Installation and Customization Many small drag chains come with modular components, making them easy to install and customize based on the specific needs of the application. This adaptability ensures that engineers can design systems that are both efficient and effective.

5. Increased Safety Protecting cables and pneumatic lines significantly enhances workplace safety. By preventing entanglement and exposure to hazardous conditions, drag chains reduce the likelihood of accidents that can occur with loose cabling.

Choosing the Right Small Drag Chain

When selecting a small drag chain for an application, several factors must be considered

- Size and Weight The dimensions of the drag chain must match the size of the cables or hoses it will carry. Additionally, the weight capacity should be taken into account to ensure that it can handle the expected load during operation.

- Material Drag chains are made from various materials, including plastic, steel, and aluminum. The choice of material affects the chain’s strength, flexibility, and resistance to environmental factors such as temperature and moisture.

- Flexibility and Bend Radius The design of the drag chain should accommodate the specific movement needs of the machinery. The bend radius is a critical factor that allows for smooth operation without straining the cables.

- Environmental Conditions Consideration must also be given to the operating environment. Factors such as exposure to chemicals, extreme temperatures, or dust may dictate the material and design of the drag chain.

Conclusion

In conclusion, small drag chains are a fundamental yet often overlooked component in modern machinery. Their ability to protect and manage cables and hoses while supporting dynamic movement makes them invaluable in various industrial applications. By understanding their significance and choosing the right type for specific needs, engineers can enhance the efficiency, reliability, and safety of their systems, paving the way for continued innovation in engineering and automation.