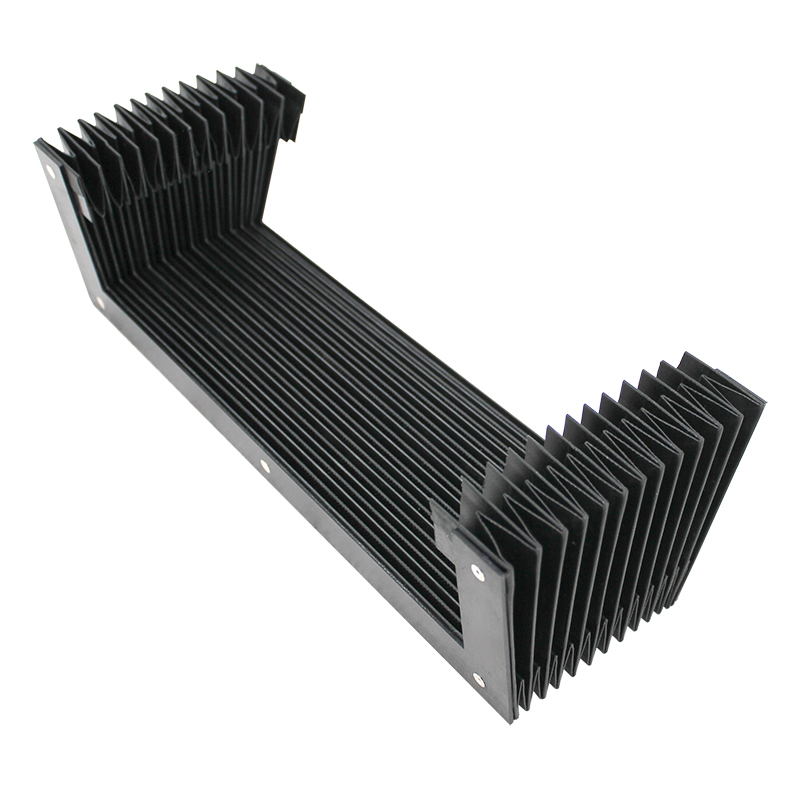

split corrugated plastic conduit

Understanding Split Corrugated Plastic Conduit Applications and Benefits

In the ever-evolving landscape of electrical and telecommunications infrastructure, the choice of conduit materials plays a crucial role in ensuring efficient installation and long-lasting performance. One notable option that has gained popularity in recent years is the split corrugated plastic conduit. This innovative solution offers a myriad of benefits that cater to various applications, making it a preferred choice for many contractors and engineers.

What is Split Corrugated Plastic Conduit?

Split corrugated plastic conduit is a type of electrical conduit made from high-density polyethylene (HDPE) or similar thermoplastics. Unlike traditional rigid conduits, this conduit features a unique split design that allows for easy installation and removal of wires and cables. The corrugated surface provides flexibility while maintaining a durable structure that can withstand external pressures and harsh environmental conditions.

Key Features

1. Ease of Installation The split design is one of the most notable features of this conduit. It allows installers to easily open the conduit and insert or remove cables without needing specialized tools. This ease of use significantly reduces installation time and labor costs.

2. Flexibility The corrugated structure provides a high degree of flexibility, allowing the conduit to bend around corners and obstacles without breaking. This feature is particularly beneficial in complex installations where straight runs are not possible.

3. Durability Made from robust materials, split corrugated plastic conduit offers excellent resistance to chemicals, moisture, and abrasion. It can endure extreme temperatures and is suitable for both indoor and outdoor applications.

4. Lightweight Compared to traditional metal conduits, split corrugated plastic conduits are much lighter, making them easier to handle and transport. This lightweight nature contributes to reduced shipping costs and simpler project management.

5. Cost-Effective With lower material costs and reduced labor requirements for installation, split corrugated plastic conduits are often more cost-effective than their metal counterparts. This makes it an attractive option for budget-conscious projects.

split corrugated plastic conduit

Applications

Split corrugated plastic conduit is versatile and finds applications in various sectors, including

- Telecommunications It is widely used to protect and route fiber optic cables and other telecommunications wiring, ensuring they are shielded from environmental hazards.

- Electrical Installations Ideal for residential, commercial, and industrial electrical systems, this conduit helps organize wiring, reducing clutter and making maintenance easier.

- Automotive and Transport In the automotive industry, split corrugated plastic conduit is used to protect wiring harnesses, preventing damage from friction and weather.

- Renewable Energy With the growth of solar and wind energy solutions, this conduit solution is increasingly applied in the protection of wiring for solar panels and wind turbines.

Environmental Considerations

In today’s environmentally conscious world, manufacturers are increasingly focusing on producing sustainable products. Many split corrugated plastic conduits are made from recyclable materials and are designed to have a long service life, reducing the need for frequent replacements. Additionally, the lightweight nature of plastic conduits contributes to lower energy consumption during transportation.

Conclusion

Split corrugated plastic conduit is an exceptional alternative to traditional conduit options, offering an array of benefits including ease of installation, flexibility, durability, and cost-effectiveness. Its applications span across various industries, from telecommunications to renewable energy, making it a versatile choice for contractors and engineers alike. As technology advances and the demand for efficient and sustainable solutions grows, the popularity of split corrugated plastic conduit is likely to increase, solidifying its place as a staple in modern infrastructure development. In this era of innovation, embracing such solutions will be key to optimizing performance and ensuring the longevity of electrical and telecommunications systems.