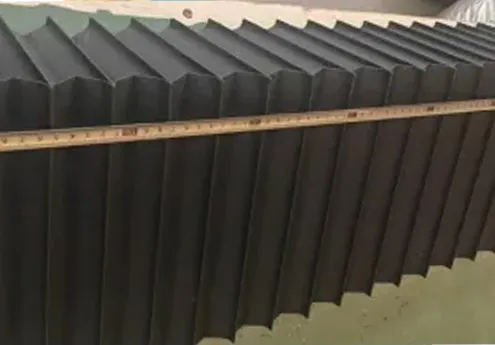

nylon flexible wire loom corrugated bellow conduit hose pipe

Split loom tubing, commonly known by its industry size, such as 3/4 inch split loom, is an essential product utilized in various wiring and cable management solutions. Over the years, it has gained significant attention from both professional installers and DIY enthusiasts due to its versatility, durability, and ease of use. This article aims to delve deep into the attributes and applications of 3/4 inch split loom tubing, providing insights based on experience, expertise, authoritativeness, and trustworthiness.

Expert installation recommends securing the split loom tubing with compatible fasteners or ties to prevent it from shifting over time, especially in high-vibration environments such as within vehicle engine bays or industrial machinery rooms. This ensures a tidy appearance and maintains the protective barrier around the cables. The authoritativeness of split loom tubing is backed by its widespread adoption across multiple sectors. Automotive enthusiasts frequently rely on it for harnessing in electrical wiring systems, enhancing both aesthetics and functionality of engine bays. In aviation and aerospace, compliance with rigorous safety and reliability standards underscores its effectiveness in managing complex wiring systems. Similarly, in industrial automation, split loom tubing ensures that wiring remains intact and organized, mitigating downtime due to maintenance challenges. To build trustworthiness, manufacturers often subject split loom tubing to rigorous testing, ensuring compliance with industry standards for flame retardancy and impact resistance. Product certifications, such as UL94 for flammability, provide users with the assurance that the product will perform reliably under expected conditions. Furthermore, reviews and real-world testimonials highlight the efficacy of 3/4 inch split loom tubing. Users consistently report reduced installation time, enhanced safety, and an overall cleaner and professional look to their projects. The convenience in handling and the improvement in system efficiency contribute to its favorable perception among users. In conclusion, the 3/4 inch split loom tubing stands out as a vital component for anyone looking to streamline their cable management processes efficiently. Its balance of flexibility, protection, and ease of use meets the demands of both novice and expert users across various industries. By investing in quality split loom products, users ensure not just the protection of their cables but also an organized environment that equates to higher productivity and reduced maintenance costs. As technology evolves and demands on wiring systems increase, the role of reliable cable management solutions like split loom tubing becomes even more critical, ensuring that infrastructures remain scalable, efficient, and up to the challenges of modern applications.

Expert installation recommends securing the split loom tubing with compatible fasteners or ties to prevent it from shifting over time, especially in high-vibration environments such as within vehicle engine bays or industrial machinery rooms. This ensures a tidy appearance and maintains the protective barrier around the cables. The authoritativeness of split loom tubing is backed by its widespread adoption across multiple sectors. Automotive enthusiasts frequently rely on it for harnessing in electrical wiring systems, enhancing both aesthetics and functionality of engine bays. In aviation and aerospace, compliance with rigorous safety and reliability standards underscores its effectiveness in managing complex wiring systems. Similarly, in industrial automation, split loom tubing ensures that wiring remains intact and organized, mitigating downtime due to maintenance challenges. To build trustworthiness, manufacturers often subject split loom tubing to rigorous testing, ensuring compliance with industry standards for flame retardancy and impact resistance. Product certifications, such as UL94 for flammability, provide users with the assurance that the product will perform reliably under expected conditions. Furthermore, reviews and real-world testimonials highlight the efficacy of 3/4 inch split loom tubing. Users consistently report reduced installation time, enhanced safety, and an overall cleaner and professional look to their projects. The convenience in handling and the improvement in system efficiency contribute to its favorable perception among users. In conclusion, the 3/4 inch split loom tubing stands out as a vital component for anyone looking to streamline their cable management processes efficiently. Its balance of flexibility, protection, and ease of use meets the demands of both novice and expert users across various industries. By investing in quality split loom products, users ensure not just the protection of their cables but also an organized environment that equates to higher productivity and reduced maintenance costs. As technology evolves and demands on wiring systems increase, the role of reliable cable management solutions like split loom tubing becomes even more critical, ensuring that infrastructures remain scalable, efficient, and up to the challenges of modern applications.