split tubing

Understanding Split Tubing Applications and Benefits

In various industries, maintaining the integrity of wiring and tubing is paramount for safety and efficiency. One product that plays a crucial role in achieving this is split tubing. Split tubing, also known as split wire loom or spiral cut tubing, is a flexible covering used to protect and organize wires and cables. This article will explore what split tubing is, its applications, and the benefits it provides across different sectors.

What is Split Tubing?

Split tubing is a tubular sheath made from materials like polyethylene, nylon, or PVC, designed with a longitudinal cut that allows it to be easily applied over wires and cables. The split design facilitates quick installation without having to disconnect any existing wiring. This unique feature makes split tubing an excellent choice for protecting delicate cables during assembly, maintenance, or modification tasks.

The materials used in split tubing vary widely, which allows it to be suited for different environments. For example, some types may be made from heat-resistant materials for high-temperature applications, while others may offer chemical resistance for use in harsher industrial settings.

Applications of Split Tubing

Split tubing has a broad range of applications across numerous industries. Here are some common uses

1. Automotive In the automotive industry, split tubing is often used to protect wiring harnesses. It shields the wiring from abrasion, heat, and moisture, which are common in automotive environments. By organizing the wires, it also simplifies maintenance and repairs.

2. Electronics In consumer electronics, split tubing provides a neat and organized appearance for cable management inside devices. It prevents wires from tangling and reduces the risk of short circuits, enhancing durability and performance.

3. Aerospace In the aerospace sector, where reliability is crucial, split tubing is employed to protect wiring from extreme temperatures and environmental factors. Its lightweight nature also contributes to overall energy efficiency in aircraft.

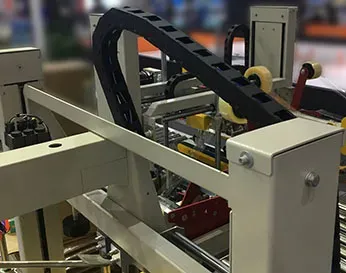

4. Industrial Applications Many industrial settings utilize split tubing for protecting cables that are exposed to friction or sharp edges. It can be found in machinery, conveyor systems, and other equipment where wire integrity is vital for operation.

split tubing

5. Home and DIY Projects For those involved in home improvement or DIY projects, split tubing is an ideal solution for organizing and protecting wires. It can be used indoors or outdoors, helping to prevent deterioration and wear over time.

Benefits of Using Split Tubing

The advantages of using split tubing are numerous

- Protection One of the key benefits is its ability to protect wires from abrasion, moisture, chemicals, and heat. This increases the lifespan of the wires and ensures functional reliability.

- Organizational Efficiency Split tubing helps in managing multiple wires by keeping them bundled together, reducing clutter, and minimizing the risk of tangles. This organization aids in troubleshooting and repairs.

- Ease of Installation The split design allows for quick and hassle-free installation. Users can easily slide it over existing wires without the need for disconnection, saving time and effort.

- Customizability Split tubing is available in various colors, sizes, and materials, allowing users to select the right option based on specific needs and applications.

- Cost-Effective By extending the life of cables and reducing maintenance needs, split tubing can lead to significant cost savings over time. Its low upfront cost combined with its protective benefits makes it a valuable investment.

Conclusion

In conclusion, split tubing is an essential component in the protection and management of wires across multiple industries. Its unique split design, coupled with various material options, makes it a versatile choice for applications ranging from automotive to aerospace, and even everyday household projects. The benefits it offers, including protection, organizational efficiency, ease of installation, and cost-effectiveness, underscore its importance. As technology continues to evolve and industries demand greater reliability, split tubing is poised to remain a fundamental tool in ensuring the long-term integrity of wiring systems. Whether you are a professional in a specific industry or a DIY enthusiast, understanding and utilizing split tubing can help achieve a safer and more efficient environment for electrical components.