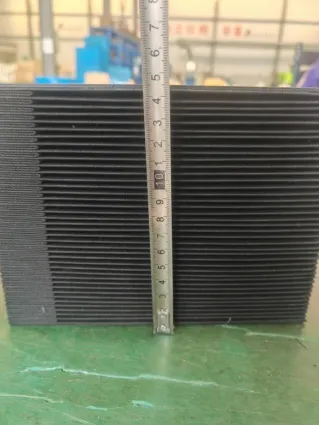

corrugated loom tubing

Navigating the vast array of components in industrial and consumer applications can be daunting, especially when those components serve crucial roles, such as split wire tubing. This seemingly humble piece of equipment is indispensable for professionals who prioritize the protection and organization of electrical wiring systems.

The installation process of split wire tubing is a straightforward endeavor, yet it requires attention to detail to maximize its benefits. To achieve optimal performance, ensure that the tubing is aligned with the wire run and gently press along the split to secure a snug fit. It is crucial to allow some slack at both ends to accommodate movement and avoid undue stress on connections. Furthermore, for outdoor or high-vibration installations, it is advisable to use additional fasteners or wraps to secure the tubing and prevent slippage. In professional environments where precision and reliability are paramount, choosing the right size of split wire tubing is essential. Sizes range from small, ideal for individual wires, to large, capable of encasing entire bundles of cables. The correct size not only ensures maximal protection but also contributes to a neater, more organized cable management system. Effort should be made to regularly check installations, replacing any damaged or worn-out tubing promptly to maintain standards. In conclusion, as industries continue to expand and the demand for organized, safe wiring solutions grows, split wire tubing proves to be an invaluable asset. Its versatility, ease of installation, and protective qualities underscore its status as a go-to solution for managing electrical and data cabling systems. Selecting high-quality materials from reputable manufacturers can further enhance performance, lending an air of authority and trustworthiness to your projects. In the realm of cable management, the reliability and efficiency of split wire tubing remain unmatched, ensuring a well-maintained and hazard-free environment.

The installation process of split wire tubing is a straightforward endeavor, yet it requires attention to detail to maximize its benefits. To achieve optimal performance, ensure that the tubing is aligned with the wire run and gently press along the split to secure a snug fit. It is crucial to allow some slack at both ends to accommodate movement and avoid undue stress on connections. Furthermore, for outdoor or high-vibration installations, it is advisable to use additional fasteners or wraps to secure the tubing and prevent slippage. In professional environments where precision and reliability are paramount, choosing the right size of split wire tubing is essential. Sizes range from small, ideal for individual wires, to large, capable of encasing entire bundles of cables. The correct size not only ensures maximal protection but also contributes to a neater, more organized cable management system. Effort should be made to regularly check installations, replacing any damaged or worn-out tubing promptly to maintain standards. In conclusion, as industries continue to expand and the demand for organized, safe wiring solutions grows, split wire tubing proves to be an invaluable asset. Its versatility, ease of installation, and protective qualities underscore its status as a go-to solution for managing electrical and data cabling systems. Selecting high-quality materials from reputable manufacturers can further enhance performance, lending an air of authority and trustworthiness to your projects. In the realm of cable management, the reliability and efficiency of split wire tubing remain unmatched, ensuring a well-maintained and hazard-free environment.