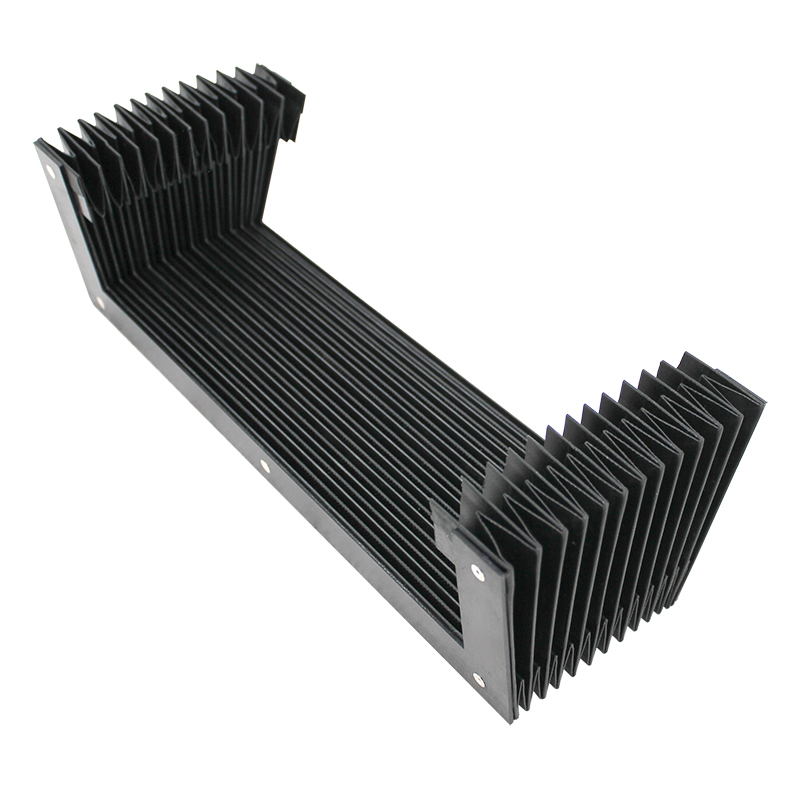

High-Quality Steel Bellow Covers for Enhanced Protection

The Importance of Steel Bellow Covers in Industrial Applications

Steel bellow covers are essential components in various industrial applications, providing protection and enhancing the longevity of machinery and equipment. These durable protective covers allow for the safe and efficient operation of moving parts, particularly in environments that may expose them to contamination or abrasive materials.

One of the primary functions of steel bellow covers is to shield machinery from dirt, dust, and other external particles that can cause wear and tear. In manufacturing settings, machines are often subjected to harsh conditions, which can lead to decreased efficiency and premature failure. By using steel bellow covers, operators can ensure that critical moving parts, such as linear guides and ball screws, are well-protected. This protection not only extends the life of the components but also minimizes the need for costly repairs and downtime.

Furthermore, steel bellow covers provide a crucial barrier against coolant, oil, and other substances common in machining environments. These fluids can contaminate unclear internal parts, leading to corrosion and malfunctions. By preventing these substances from infiltrating mechanical systems, bellow covers contribute significantly to the overall reliability and productivity of industrial equipment.

steel bellow cover

In addition to their protective benefits, steel bellow covers are designed to accommodate the range of movement required by machinery. Their flexible design allows for smooth motion while keeping components shielded from external threats. This adaptability means that bellow covers can be used in a variety of applications, from CNC machines to vertical milling centers, ensuring consistency in performance across different types of machines.

The manufacturing of steel bellow covers includes a variety of processes, such as stamping and welding, to ensure that they can withstand the pressures and demands of their respective environments. Quality materials and precision engineering are crucial in creating bellow covers that can endure extremes in temperature and pressure, a common challenge in industrial settings.

Moreover, the customization options available for steel bellow covers make them versatile solutions for unique equipment needs. Engineers can design bellow covers in different shapes, sizes, and materials, ensuring they fit perfectly and provide the necessary protection for any application.

In conclusion, steel bellow covers play a vital role in protecting machinery from environmental hazards and improving operational efficiency. Their durability, flexibility, and ease of customization make them indispensable in various industrial applications. As industries continue to evolve and demand greater reliability and longevity from their equipment, the significance of steel bellow covers will only increase, underscoring their fundamental role in modern manufacturing and engineering practices.